APC control panel: WeldEye

_300x402.jpg)

This chapter is about the optional WeldEye feature in X5 APC wire feeder models.

The use of this WeldEye feature and cloud service require an up-to-date X5 FastMig equipment and a valid Kemppi WeldEye Quality Management subscription. For more information on WeldEye, refer to weldeye.com or contact your Kemppi representative.

The built-in WeldEye feature collects and passes on welding data, keeping it synchronized between the welding equipment and WeldEye cloud service. The WeldEye cloud service can be accessed using a desktop computer and an internet browser.

To take the WeldEye feature in use, the equipment must be connected to the internet via the built-in wireless connection (WLAN). Refer to Wireless connection (WLAN) for instructions.

The welding equipment must also be added to your WeldEye account in the WeldEye cloud service. Once the equipment is connected to the internet and added into WeldEye, the equipment logs in to WeldEye automatically. For more information on using the WeldEye cloud service, refer to the WeldEye documentation in your organization's WeldEye cloud service.

|

The selections in the WeldEye view are made beforehand for the weld or work in question. The weld data is then saved along with these selections in the WeldEye cloud service after the work has been completed. |

|

If the welding equipment loses the internet connection during work, the weld data is saved locally and synchronized with the WeldEye cloud service once the connection has been restored. |

|

If the WPS referred to in the selected work order is specified for another welding mode (e.g., TIG) than what is currently selected (e.g., MIG), it is indicated in the WeldEye view as a welding mode change recommendation. Also, the WPS referred to is not available in the WPS selection menu until the welding mode is changed to correspond with the WPS process. |

|

WeldEye is a highly configurable welding management software. Depending on your WeldEye cloud service settings, some of the attributes or features mentioned here may be disabled or not used in your organization. Refer to your WeldEye administrator for more information. |

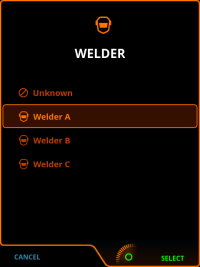

Selecting welder

The WeldEye view allows selecting the welder for the welding work at hand. The welders are predefined in the WeldEye cloud service.

| 1. | Go to the WeldEye view and select "Welder" by turning and pressing the right control knob. |

_200x268.jpg)

| 2. | Select your name on the list. |

If your name is not on the list, you can leave the welder unselected (unknown).

|

The WeldEye's welder selection is not linked with the user selection in the device settings. |

Selecting status

The welder's status can also be reported in the WeldEye view. This is used primarily for reporting when the actual welding work has been interrupted temporarily, typically due to maintenance or some other reason. The status options (reason codes) are specified in the WeldEye cloud service.

By default, the status is not defined, which is indicated by the text "Undefined".

| 1. | In the WeldEye view, select "Status" by turning and pressing the right control knob. |

| 2. | Select the status from the menu. |

When the welding commences, the status is automatically reset to undefined.

Selecting work order and weld

In the WeldEye view you can select digital work orders assigned to you in the Kemppi WeldEye cloud service. The work order feature is enabled by default.

|

In case the use of work orders has been disabled in the WeldEye settings, welds are selected directly from a list (categorized by projects and/or weld lists), and welder-specific weld filtering is not applied. |

| 1. | In the WeldEye view, select "Work order" by turning and pressing the right control knob. |

| 2. | Select a work order from the list. |

_200x268.jpg)

| 3. | If the work order has more than one weld or weld pass included, select also the specific weld or weld pass to be welded. |

_200x268.jpg)

The welds and weld passes on the work order can have digital WPSes (welding procedure specifications) attached to them. When a work order is selected, and it has a WPS or WPSes included, a WPS row is shown in the WeldEye view.

|

A digital WPS may contain one or more requirements or recommendations for the welder's qualification and the filler material and gas to be used. If the welder or the materials selected do not meet the criteria on the work order, it is indicated with a caution symbol. |

Applying digital WPS

If the selected weld on the work order includes a digital WPS that has already been linked to a memory channel, that memory channel is automatically activated. For more information on digital WPSes on the X5 equipment, refer to APC control panel: WPS view.

|

If the device-level user is changed in the device settings, also the saved memory channels change. Therefore, the digital WPS linking with memory channels must be established for each device-level user separately. |

If no WPS is selected, you can go to the WPS row in the WeldEye view, and select an available WPS.

Also WPS linking or re-linking can be accomplished directly from the WeldEye view. To link or re-link WPS:

| 1. | In the WeldEye view, select the weld and weld pass below the WPS row by turning and pressing the right control knob. |

_200x268.jpg)

| 2. | In the menu that opens, select the weld pass and WPS linking you want to edit. |

_200x268.jpg)

| 3. | Open the actions menu and select "Link to channel". |

_200x268.jpg)

| 4. | In the memory channel list, select the memory channel you want to link the WPS with. |

>> If needed, select "Filter channel list" to filter memory channels based on the WPS specifications.

_200x268.jpg)

You can access the weld pass selection of the active WPS by selecting the weld pass row in the WeldEye view. In the selection dialog that opens, all of the weld passes are listed and each of them can be linked to a memory channel.

When a WPS is linked to a memory channel, that channel is automatically applied.

Entering material information

The lower section of the WeldEye view shows the filler wire material and gas information including their batch identification (if and as required).

|

The material information filled in the WeldEye view should always match with the filler material and gas used in welding (i.e., what is installed in the welding equipment). |

|

A digital WPS may include several recommendations for filler material and gases. You can check and change the recommended materials in the WeldEye view. |

|

A digital WPS may contain one or more requirements or recommendations for the welder's qualification and/or the filler material and gas to be used. If the welder or the materials selected do not meet the criteria, it is indicated with a caution symbol. |

| 1. | Select the filler material and gas in the corresponding menus by turning and pressing the right control knob. |

_200x268.jpg)

_200x268.jpg)

| 2. | Select or enter also the batch information if/as required with the right control knob. |

>> A virtual keyboard is used for entering the filler or gas batch identification manually, if the correct batch identification is not already on the list. Once the batch identification information has been entered for the first time, it becomes available as a pre-filled list option for later use.

_200x268.jpg)

| 3. | Ensure that the selected filler material and gas are installed and ready for welding. |

Selecting work piece

Also the work piece information can be used and saved in WeldEye. If this feature is enabled in the WeldEye cloud service settings, the work piece selection is available in the WeldEye view.

_200x268.jpg)

| 1. | Select the work piece by turning and pressing the right control knob. |

| 2. | Enter the work piece information using the virtual keyboard with the right control knob. |

_200x268.jpg)

Completing work

Once work (work order, weld, weld pass) has been completed, it can be confirmed in the weld status view that opens right after finishing a weld. This view also replaces the standard weld data view in WeldEye use.

If the work has not been marked as completed right after finishing the weld, it can be done also in the WeldEye view:

| 1. | Go to the work you finished, and select "Weld status" by turning and pressing the right control knob. |

| 2. | In the weld status dialog, select "Complete pass", "Complete weld" or "Complete work order", depending on which work stage you're finishing. |

_200x268.jpg)

_200x268.jpg)

_200x268.jpg)

When completing a weld pass, the weld length can be entered in the weld status view by selecting the length symbol and "Set length" with the right control knob button.

_200x268.jpg)

|

Even if all of the individual welds are marked as completed, the work order itself must also be completed in the WeldEye view. |

|

It is possible to mark welds and work orders completed even if they would contain incomplete weld passes and/or welds. Make sure that all of the welding work has been completed as required before completing welds or work orders in WeldEye. |

More related feature descriptions here:

>> Digital Welding Procedure Specification (dWPS)

>> WeldEye