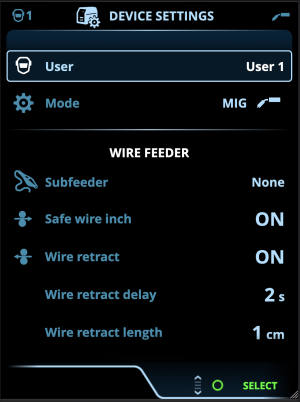

AP/APC control panel: Device settings

Changing settings

| 1. | Turn the right control knob to highlight the desired settings parameter. |

| 2. | Press the right control knob to select the settings parameter for adjustment. |

| 3. | Turn the right control knob to select the settings value. |

>> Depending on the settings parameter to be adjusted, refer also to the Settings table below for more details.

| 4. | Confirm the new value / selection and close the adjustment view by pressing the right control knob. |

Users

The system settings can be customized for up to 10 different users. In addition to the system settings, the memory channels are user-specific. Each user can have up to 100 MIG channels, 10 TIG channels, 10 MMA channels and 10 gouging channels. The memory channel and system settings are saved automatically for the logged-in user.

Settings

| Parameter | Parameter value | Description |

|---|---|---|

| User | Current user | There is always a logged-in user in the system. When a new user logs in, the previous user is automatically logged out. In case of a mixed double wire feeder installation where the other wire feeder is a Manual model, user 1 is automatically applied and user change is disabled. |

| Mode | MIG/TIG/MMA/Gouging | Note: For TIG welding the polarity (+/-) must be switched. For more information, refer to Installing cables (X5 WF 200, X5 WF 300, X5 WF HD300). |

| Demo time | OFF/ON | The demo time feature allows you to try out optional welding features and functions without a license for a limited time. The total available demo time is 3 hours. The demo time passes only when welding using a welding feature you don't have a license for. When the demo time is set to ON, the remaining time is shown on the display. |

| Settings lock | Not in use / Unlocked / Locked | Settings lock is used to restrict changes to a predefined set of welding parameters and device settings. When this feature is turned on, the settings can be locked and unlocked in the device settings. A PIN code can be set for the settings lock. For more information, refer to Settings lock. |

| Remote control | OFF / Hand remote / Gun remote Default = OFF |

If remote controller is not connected, this selection is not available. Note: This setting does not affect and is not affected by the HR55 remote control. |

| Remote mode (with 1-knob remote control) |

Wire feed speed or current / Channel | This determines what is changed with the remote, welding parameter or memory channel (available channels: 1...5). The parameters are process-specific. If remote controller is not connected and remote not selected, this selection is not available. Note (2-knob remote): When the remote mode is set to 'Channel', only the left remote control knob is in use. Note: If the HR55 remote control is also connected, the parameter that is selected here cannot be adjusted with the HR55 remote control. |

| Remote mode (with 2-knob remote control) |

Welding parameters / Channel | |

| Subfeeder (in MIG mode and with X5 Wire Feeder 300 only) |

Subfeeder model / None Default = None |

If a compatible subfeeder is connected, select the subfeeder from the list. Compatible subfeeders: SuperSnake GTX (10m, 15m, 20m, 25m), Binzel PP401D, Binzel PP36D. |

| Safe wire inch (with MIG only) |

OFF/ON | When ON, and the arc doesn't ignite, the filler wire is fed 5 cm When OFF, 5 m of filler wire is fed. |

| Wire retract | OFF/ON | This is an automatic wire retract feature. Once the arc is extinguished, the wire is retracted for additional safety. The user can change the wire retract delay and length settings. Note: Wire retract function is disabled if a subfeeder is connected. |

| - Wire retract delay | 2...10 s, step 1 Default = 5 s |

|

| - Wire retract length | 1...10 cm, step 1 Default = 2 cm |

|

| Language | Available languages | This allows the user to select the control panel language from a list of available languages. |

| Weld data time | 0...30 s, step 1 0 = OFF Default = 5 s |

This defines if and how long the weld data summary is shown after each weld. |

| Weld data average | Without slopes / Entire weld Default = Without slopes |

This feature allows the user to change how the weld data averages are calculated: with or without the slope phases in the beginning and in the end of the weld. This setting affects the calculation of the averages for the following: welding voltage (terminal and arc voltage), welding current, welding power and wire feed speed. |

| Brightness | 1...10 | The control panel display brightness. |

| Date | Current date | Date setting. |

| Time (24h) | Current time | Time setting in 24h format. |

| Screensaver | OFF/1...120 min, step 1 Default = 5 min |

The screensaver image is shown on display after the set time period. By default, the Kemppi logo is shown. To change the screensaver image, refer to USB update. |

| Display off | OFF/1...120 min, step 1 Default = 5 min |

The control panel display is turned off after the set time period. The right control knob light is lit when the display is off. |

| Cable calibration (with MIG only) |

Start/Cancel | The date and time and the calibration information of the previous calibration is also shown. Refer to Calibrating welding cable for cable calibration. |

| Water cooling | OFF/Auto/ON Default = Auto |

When ON is selected, the coolant is circulated continuously, and when Auto is selected, the coolant is circulated only during welding. |

| Gas guard | OFF/ON Default = OFF |

Gas guard prevents welding without shielding gas. This setting is not available if the gas guard is not installed. |

| VRD (with MMA and gouging only) |

OFF/12V/24V Default = OFF |

Voltage reduction device (VRD) reduces the open-circuit voltage to maintain below a certain voltage value. |

| Backup | (Selection) | This allows the settings to be saved on a connected USB memory stick. |

| Restore | (Selection) | This allows the settings to be restored from a connected USB memory stick. |

| Factory reset | Start/Cancel Default = Cancel |

This resets the equipment to factory settings. |