Support for push-pull welding torches

A third party push-pull welding torch can be connected to R500 Wire Feeder HD EUR+ using either of the following:

| • | Direct motor control |

| • | Analog output |

Direct motor control

The direct motor control means that the R500 Wire Feeder HD EUR+ controls the push-pull torch's motor directly (the push-pull welding torch's synchronization unit is not in use).

R500 Wire Feeder HD EUR+ supports the following push-pull welding torches in direct motor control mode:

| Welding torch | Notes |

|---|---|

| Dinse FD300 | Refer to Connecting Dinse FD300 welding torch (R500 WF HD EUR+). |

Analog output

The R500 Wire Feeder HD EUR+ provides an analog synchronization output for connecting push-pull welding torches equipped with a synchronization unit for welding torch motor control. The analog synchronization output is available on the push-pull welding torch control cable connector's pins G and H (refer to Push-pull welding torch control cable connector). The analog synchronization output provides a low current analog voltage that corresponds linearly to the wire feed speed of the wire feeder. The output is differential, and the output voltage is positive when the wire feeder feeds the filler wire forward, and negative when it feeds the filler wire backward.

Because the output signal is not isolated from the wire feeder’s system ground, the push-pull welding torch's synchronization unit should not have any other electrical connections to the wire feeder to prevent any unwanted ground loops.

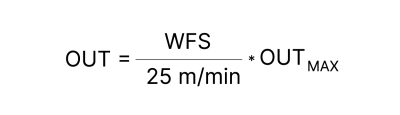

The analog output voltage corresponding to the wire feeder’s wire feed speed is calculated using the following formula:

| Symbol | Description | Notes |

|---|---|---|

| OUT | Output voltage (V) | |

| WFS |

Wire feed speed (m/min) |

Range: 0 … 25 m/min |

| OUTMAX | Output voltage range (V) | Either 10 V or 20 V depending on the AX Manager setting (refer to Device settings). |