Replacing steel wire liner

Tools needed:

|

|

|

Removing and inserting wire liner

This same method applies to both Euro connector (GX series 3 and 5) and Kemppi connector (GX series 8) welding guns, but the visual details may vary. The method is the same also for both gas- and water-cooled welding guns.

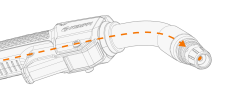

| 1. | Straighten the welding gun cable pack. |

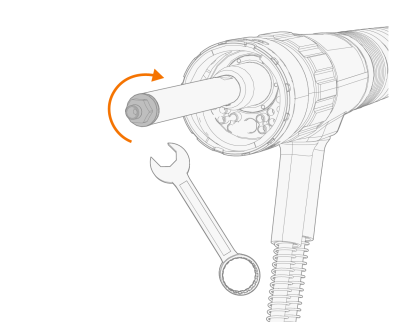

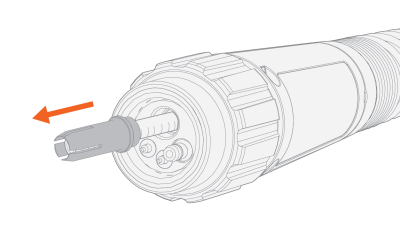

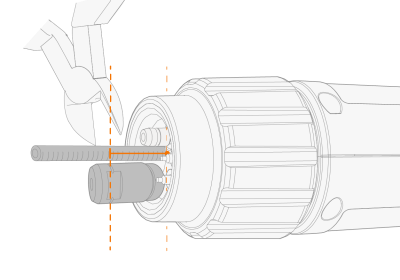

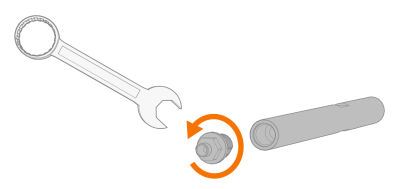

| 2. | At the wire feeder end of the cable, remove the wire liner's sleeve nut and retainer cone. |

|

The GX series 8 welding gun has a long sleeve nut and the series 8 GMN, WS and 608W models include also an additional sealing ring (*). Remove that also. |

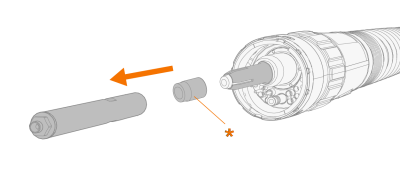

| 3. | Remove the old wire liner from the cable hose. |

|

If you still plan to use the same wire liner later, make sure not to damage the wire liner at this stage. |

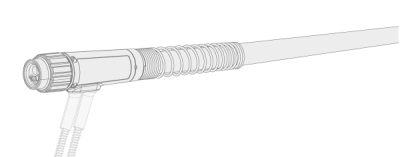

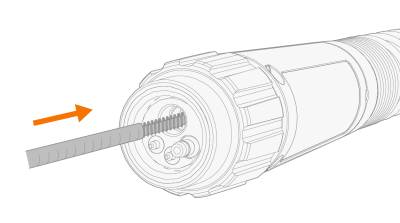

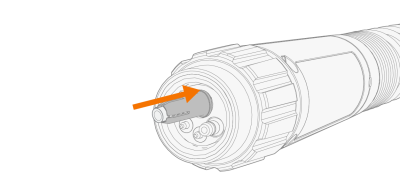

| 4. | Feed the new wire liner into the cable hose until it stops at the gun neck end. |

|

The standard steel wire liner includes a stripped steel spiral section(*) at its front end. This section goes in first. The steel wire liner for a multi-neck welding gun does not include a stripped section. |

|

To ensure that the wire liner is in the correct position, temporarily remove the welding gun contact tip. For more information on the contact tip, refer to About equipment and Assembling gun. In case of a multi-neck welding gun, the wire liner does not go into the neck. With a multi-neck welding gun, the neck is to be removed (refer to Replacing wire liner for multi-neck).

|

For finalizing the wire liner installation, refer to (depending on your welding gun model):

Installing sleeve assembly and cutting wire liner (Euro connector: series 3 and 5 welding guns) or

Installing sleeve assembly and cutting wire liner (Kemppi connector: series 8 welding guns).

Installing sleeve assembly and cutting wire liner (Euro connector: series 3 and 5 welding guns)

The method is the same for both gas- and water-cooled welding guns.

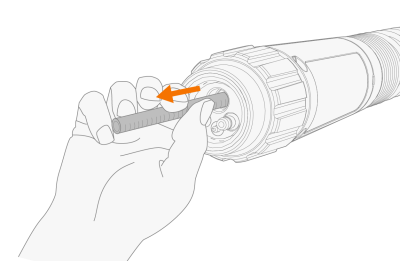

| 1. | Insert the sleeve nut next to the wire liner for measure. |

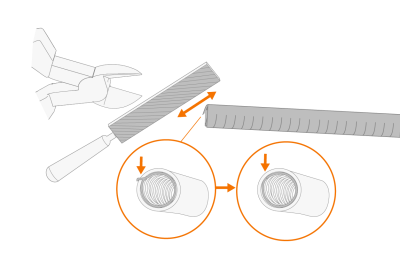

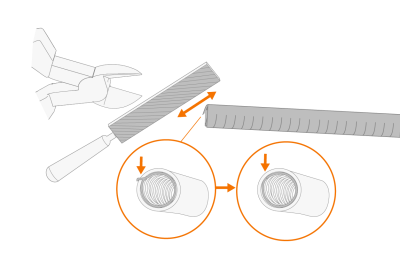

| 2. | Using side cutting pliers, cut the wire liner flush with groove in the sleeve nut end. |

| 3. | File the end of the liner. |

|

Don't leave any rough, inward edges that could potentially damage the filler wire. |

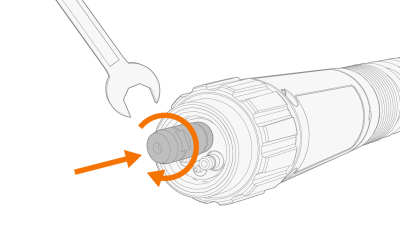

| 4. | Insert the retainer cone onto the wire liner and push it in place. |

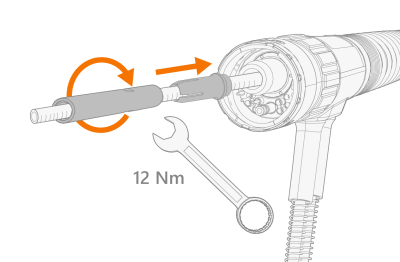

| 5. | Place the sleeve nut on the wire liner and secure it in place. Tighten to 12 Nm torque. |

Installing sleeve assembly and cutting wire liner (Kemppi connector: series 8 welding guns)

The method is the same for both gas- and water-cooled welding guns, except for the additional sealing ring with the below-mentioned models.

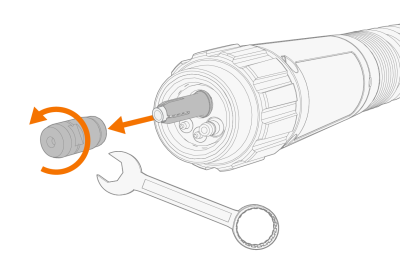

| 1. | Temporarily remove the end cap from the long sleeve nut. |

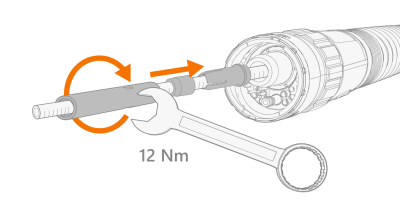

| 2. | Insert the retainer cone and sleeve nut (without the end cap) on the wire liner and secure them in place. Tighten to 12 Nm torque. |

|

Series 8 Flexlite GX models (Kemppi connector) include a longer wire liner sleeve. The series 8 GMN, WS and 608W models include also an additional sealing ring (*): |

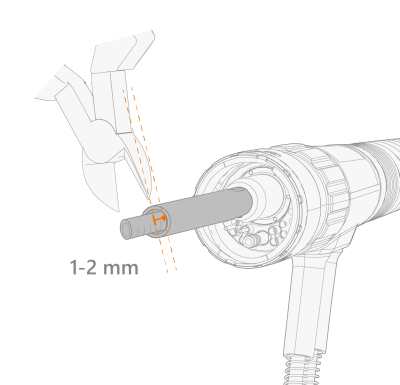

| 3. | Cut the wire liner leaving 1-2 mm of excess liner measured from the sleeve nut end. Use side cutting pliers for cutting. |

| 4. | File the end of the liner. |

|

Don't leave any rough, inward edges that could potentially damage the filler wire. |

| 5. | Install the end cap. Tighten to 1 Nm torque. |