Standard MIG welding processes in X8 MIG Welder

The processes described in this chapter are available when the MIG mode is selected. For more information on selecting the MIG mode, see Selecting welding program.

The easiest way to take a certain process into use is to select a memory channel with a welding program that uses that process. For more information, see Control Pad views: Channel.

The list of adjustable welding parameters in Settings > Parameters varies according to the selected welding program.

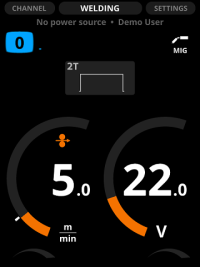

MIG

MIG is a conventional 2-knob MIG/MAG welding process that enables adjusting the wire feed speed and voltage independently. MIG does not support the Wise features.

To adjust the wire feed speed, in the Control Pad's Welding view, turn the left knob.

To adjust the voltage, in the Control Pad's Welding view, turn the right knob.

Figure: MIG Welding view

When using MIG, you can adjust the following welding parameters through Settings > Parameters:

| • | Wire Feed Speed |

>> min: adjusts the minimum set value for wire feed speed

>> max: adjusts the maximum set value for wire feed speed

| • | Voltage: adjusts the voltage (arc length). |

| • | Dynamics: -10...+10. Adjusts the short circuit behavior. On the minus side, the arc is softer (less spatter). On the plus side, the arc is harder (the arc is more stable). |

| • | StartPower: -30...+30. Adjusts the power level for arc ignition. |

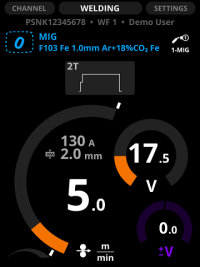

1-MIG

1-MIG is a synergic MIG/MAG welding process: when you adjust the wire feed speed, the power source adjusts the voltage accordingly. The process is suitable for all materials, shielding gases and welding positions. 1-MIG supports WiseSteel, WisePenetration+ and WiseFusion features, as well as various optimized welding programs.

To adjust the welding power / wire feed speed while welding, in the Control Pad's Welding view, turn the left knob.

To fine tune the voltage while welding, in the Control Pad's Welding view, turn the right knob.

Figure: 1-MIG Welding view

When using 1-MIG, you can adjust the following welding parameters through Settings > Parameters:

| • | Wire Feed Speed |

>> min: adjusts the minimum set value for wire feed speed

>> max: adjusts the maximum set value for wire feed speed

| • | Fine tuning: adjusts the voltage (arc length). |

| • | Dynamics: -10...+10. Adjusts the short circuit behavior. On the minus side, the arc is softer (less spatter). On the plus side, the arc is harder (the arc is more stable). |

| • | StartPower: -30...+30. Adjusts the power level for arc ignition. |

| • | StartLevel: -30...+30. Fine tunes the arc length for arc ignition. |

| • | StopPower: -30...+30. Adjusts the power level for arc stop. |

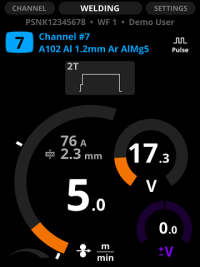

Pulse

Pulse is a synergic MIG/MAG welding process where the current is pulsed between the base current and the pulse current. The advantages of Pulse are a higher welding speed and deposition rate compared to short-arc welding, lower heat input compared to spray-arc welding, a spatter-free globular arc and smooth appearance of the weld. Pulse is suitable for all position welding. It is excellent for welding aluminium and stainless steel, especially when the material thickness is small.

Pulse supports WisePenetration+ and WiseFusion features, as well as various optimized welding programs.

To adjust the welding power / wire feed speed while welding, in the Control Pad's Welding view, turn the left knob.

To fine tune voltage while welding, in the Control Pad's Welding view, turn the right knob.

Figure: Pulse Welding view

When you set the wire feed speed, the power source adjusts the voltage and other parameters accordingly (for example, base current, pulse current, and frequency). In addition, you can adjust the following parameters through Settings > Parameters:

| • | Wire Feed Speed |

>> min: adjusts the minimum set value for wire feed speed

>> max: adjusts the maximum set value for wire feed speed

| • | Fine tuning: adjusts the voltage (arc length). |

| • | Pulse current %: Adjusts the pulse peak current. Use for controlling the droplet detachment. |

| • | Dynamics: Adjusts the short circuit behavior. On the minus side, the arc is softer (less spatter). On the plus side, the arc is harder (the arc is more stable). |

| • | StartPower: -30...+30. Adjusts the power level for arc ignition. |

| • | StartLevel: -30...+30. Fine tunes the arc length for arc ignition. |

| • | StopPower: -30...+30. Adjusts the power level for arc stop. |

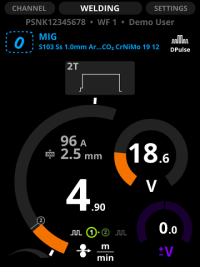

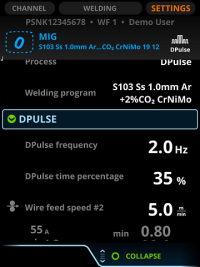

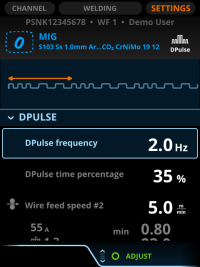

DPulse

DPulse is a pulse welding process with two separate power levels. The welding power varies between these two levels, and the parameters of each level are controlled independently. In the Welding view, toggle between level 1 and level 2 by pressing the left Control Pad button. The inactive power level is shown with a gray line on the wire feed speed diagram.

Figure: DPulse Welding view

To adjust the welding power / wire feed speed while welding, in the Control Pad's Welding view, turn the left knob.

To fine tune voltage while welding, in the Control Pad's Welding view, turn the right knob.

When using DPulse, you can adjust the following parameters through Settings > Parameters:

| • | Wire Feed Speed: adjusts the wire feed speed for level 1. |

>> min: adjusts the minimum set value for wire feed speed

>> max: adjusts the maximum set value for wire feed speed

| • | Fine tuning: adjusts the voltage (arc length). |

| • | Dynamics: Adjusts the short circuit behavior. On the minus side, the arc is softer (less spatter). On the plus side, the arc is harder (the arc is more stable). |

| • | Pulse current %: -10...+15. Adjusts the pulse peak current. Use for controlling the droplet detachment. |

| • | StartPower: -30...+30. Adjusts the power level for arc ignition. |

| • | StartLevel: -30...+30. Fine tunes the arc length for arc ignition. |

| • | StopPower: -30...+30. Adjusts the power level for arc stop. |

You can adjust the following parameters through Settings > DPulse:

| • | DPulse frequency: the frequency on which the power fluctuates between the levels. |

| • | DPulse time percentage: the relative time of the power level on the wire feed speed level 1. |

| • | Wire Feed Speed 2: adjusts the wire feed speed for level 2. |

>> min: adjusts the minimum set value for wire feed speed

>> max: adjusts the maximum set value for wire feed speed

| • | Fine tuning #2: fine tunes voltage for level 2 |

DPulse supports the WiseFusion feature and various optimized welding programs.