WeldEye with DCM

This chapter is about the WeldEye feature with a Digital Connectivity Module (DCM).

The use of this WeldEye feature and cloud service require a Digital Connectivity Module (DCM) connected to the welding equipment and a valid Kemppi WeldEye subscription. For more information on WeldEye, refer to weldeye.com or contact your Kemppi representative.

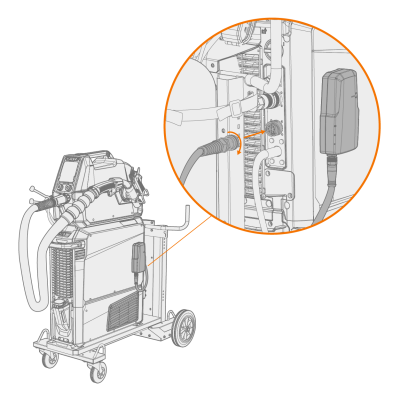

With other X5 FastMig models, an additional Digital Connectivity Module (DCM) device is required. DCM is connected directly to the X5 FastMig's control connection with the cables and adapters delivered with the DCM device.

DCM can be connected either to the wire feeder's or to the power source's control connection.

For more information on installing and using the DCM device, refer to userdoc.kemppi.com (DCM/WeldEye).

WeldEye welding management software in brief

WeldEye is a universal software solution to manage welding production. It has been designed to make everyday tasks of welding, quality and production departments easier. It offers tools for managing welding procedure specifications (WPS) and WPQRs, welding personnel and their qualifications, welding documentation, welding parameter monitoring, and heat input verification.

WeldEye's modular structure is based on various useful functions that serve the needs of wide-ranging industries and welding-related tasks:

| • | Welding procedures |

>> Includes the digital library and management of pWPS, WPQR and WPS templates according to the most important welding standards.

| • | Personnel and qualifications |

>> Includes the management and renewal processes of all personnel - welders and inspectors - qualification certificates.

| • | Quality management |

>> Includes quality verification functionalities with digital WPS and qualification compliance control against automatically collected digital welding data.

| • | Welding management |

>> Includes document register functionalities and features for comprehensive welding project documentation and management.

For more information on WeldEye, refer to www.weldeye.com.