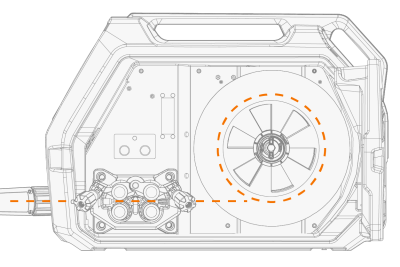

Installing and changing wire (X5 WF HD300)

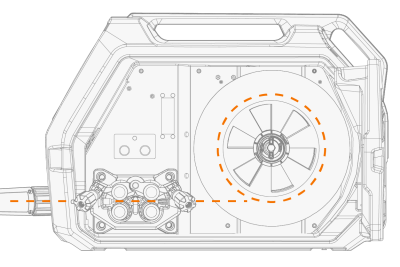

This section describes how to install the wire and spool on X5 Wire Feeder HD300.

|

Install the welding gun to the wire feeder before installing the wire spool. |

|

When changing the wire spool, remove the remaining filler wire from the welding gun and wire feed mechanism before removing the wire spool. |

To remove the wire spool:

|

1.

|

Open the wire feed cabinet door. |

|

2.

|

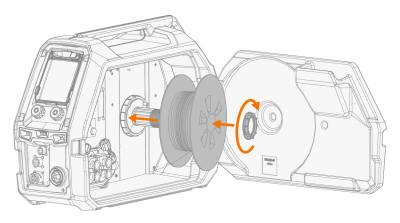

Loosen and remove the spool fastener and remove the wire spool. |

To install a new wire spool:

|

1.

|

Open the wire feed cabinet door. |

|

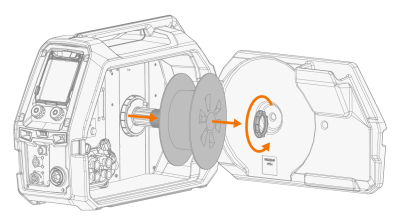

2.

|

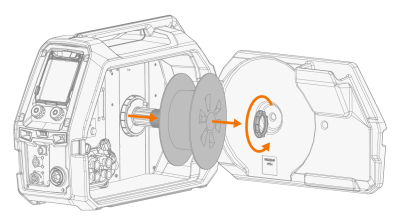

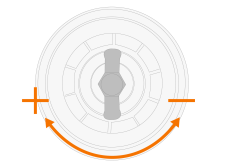

Insert the wire spool onto the spool hub. Secure the wire spool in place by inserting and tightening the spool fastener. |

|

Ensure that the wire spool is facing the right direction, the filler wire running from the bottom of the spool to the feed rolls. |

|

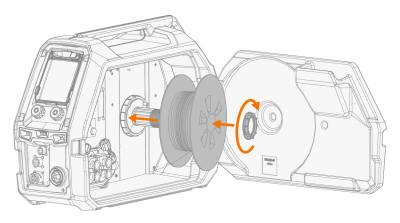

3.

|

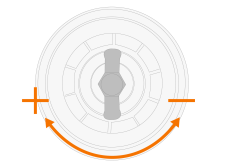

If needed, adjust the spool brake by turning the spool brake tightening knob in the center of the spool hub. |

To install the filler wire:

|

1.

|

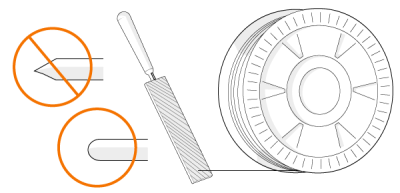

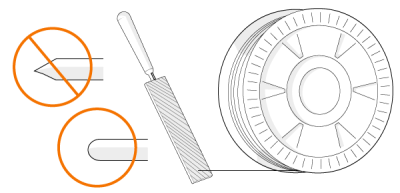

Release the filler wire end from the spool and cut off any deformed section so that the end is straight. |

|

Ensure that the filler wire does not spill from the spool when it is released. |

|

2.

|

File the tip of the filler wire smooth. |

|

Sharp edges on the filler wire tip may damage the wire liner. |

|

3.

|

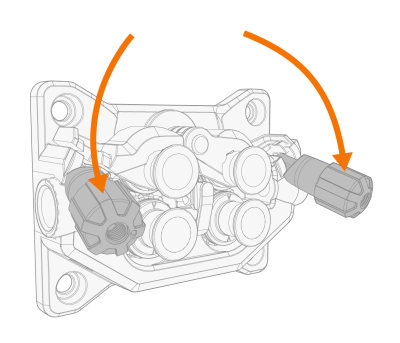

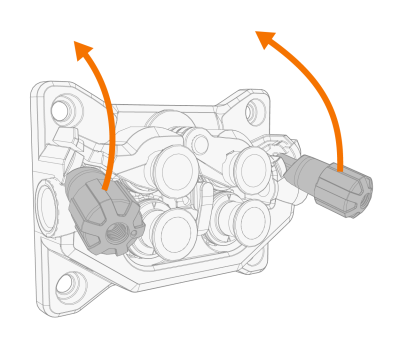

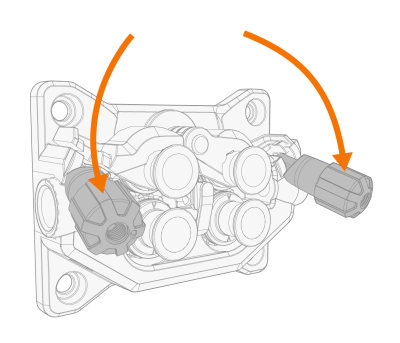

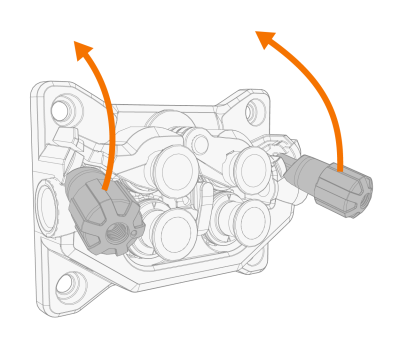

Release the pressure arms to move the feed rolls apart. |

|

4.

|

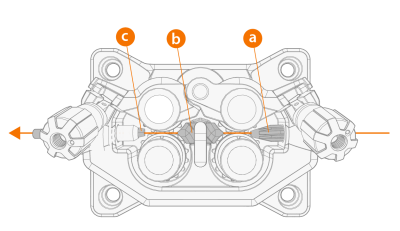

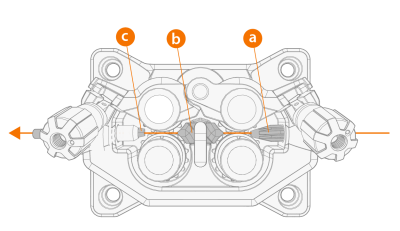

Guide the filler wire through the inlet tube (a) and middle wire guide tube (b) and into the outlet tube (c), which feeds the filler wire to the welding gun. |

|

5.

|

Push the filler wire by hand into the gun so that the wire reaches the wire liner (approx. 20 cm). |

|

6.

|

Close the pressure arms so that the filler wire is locked between the feed rolls. Ensure that the filler wire sits in the feed roll grooves. |

|

7.

|

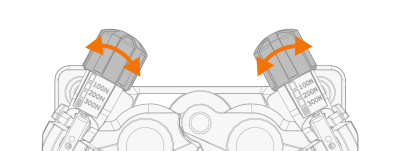

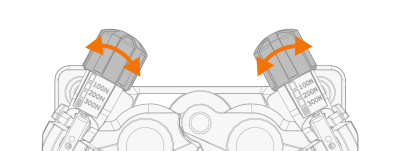

Adjust the pressure of the feed rolls with the pressure adjustment wheels. The pressure is the same for both feed roll pairs. |

The graduated scales on the pressure handle indicate the pressure applied to the feed rolls. Adjust the pressure of the feed rolls according to the table below.

| Fe/Ss solid |

V-groove

|

0.8−1.0 |

1.5−2.0 |

| ≥ 1.2 |

2.0−2.5 |

| Metal and flux cored (MC/FC) |

V-groove, knurled

|

≥ 1.2 |

1.0−2.0 |

| Self-shielded (gasless) |

V-groove, knurled

|

≥ 1.6 |

2.0−3.0 |

| Aluminum |

U-groove

|

1.0 |

0.5−1.0 |

| 1.2 |

1.0−1.5 |

| 1.4 |

1.5−2.0 |

| ≥ 1.6 |

2.0−2.5 |

|

Excessive pressure flattens the filler wire and may damage coated or cored filler wires. Excessive pressure also unnecessarily wears the feed rolls and increases gearbox load. |

|

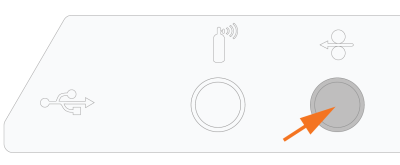

8.

|

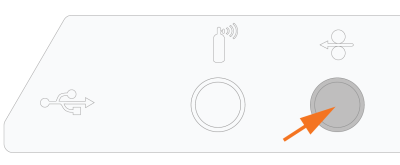

Press the wire inch button to drive the filler wire into the welding gun. Stop when the wire reaches the welding gun's contact tip. |

|

Watch out for the wire when it reaches the contact tip and exits the gun. |

|

9.

|

Before welding, ensure that the welding parameters and settings on the control panel conform to your welding setup. |

>> Refer to Using X5 AP/APC control panel for more information.