Installing gas bottle and testing gas flow

|

Handle gas bottles with care. There is a risk of injury if the gas bottle or the bottle valve is damaged! |

|

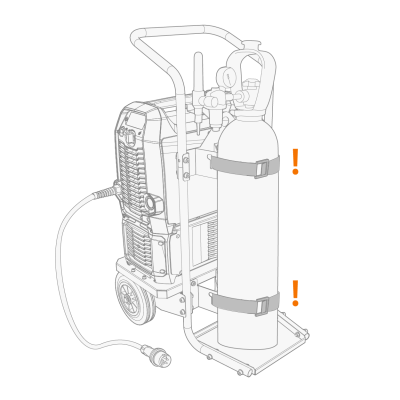

Always secure the gas bottle properly in an upright position to a special holder on the wall or on the welding equipment cart. Always keep the gas bottle valve closed when not welding. |

|

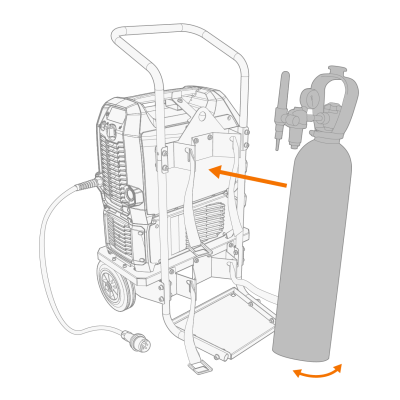

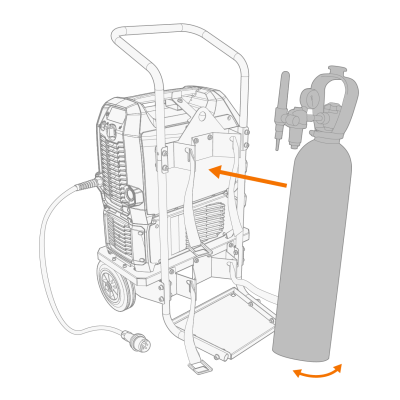

- If a cart with a gas bottle rack is used, install the gas bottle on the cart first, then make the connections.

- The maximum recommended size of the gas bottle to be installed on the T22M cart is 20 liters.

- Install the welding gun to the welding device before installing and testing the gas bottle.

|

Contact your local Kemppi dealer for choosing the gas and the equipment.

|

1.

|

Without gas bottle cart: Place the gas bottle in a suitable, secure location. |

|

2.

|

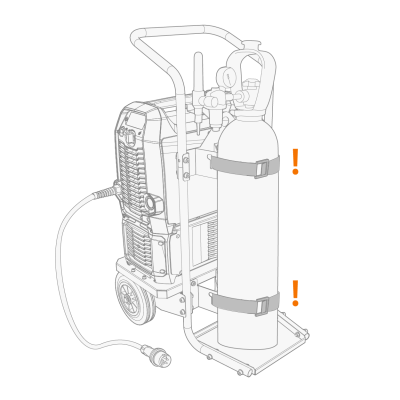

With gas bottle cart: Move the gas bottle on the transport unit's gas bottle rack and secure it in place with the straps and fixing points provided. |

|

4.

|

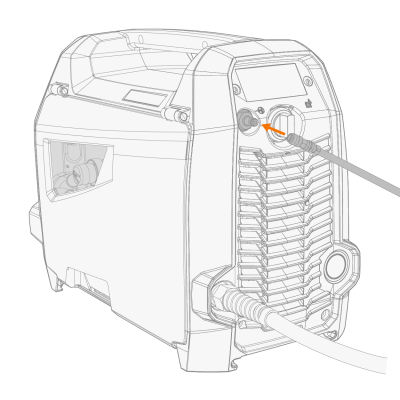

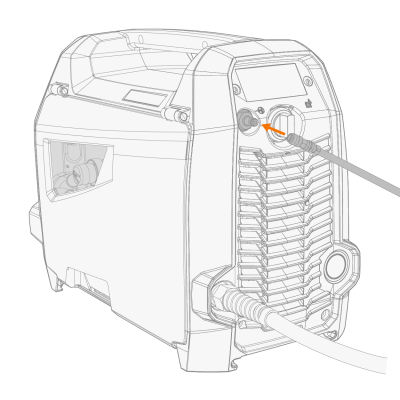

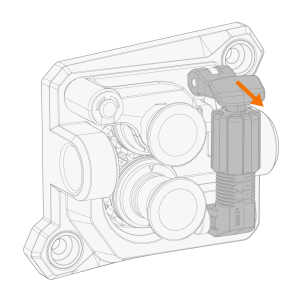

Connect the gas hose to the welding device. |

|

5.

|

Open the gas bottle valve. |

|

6.

|

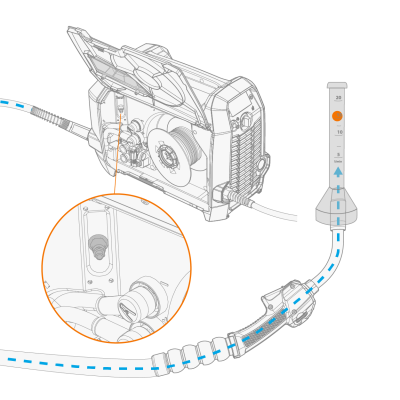

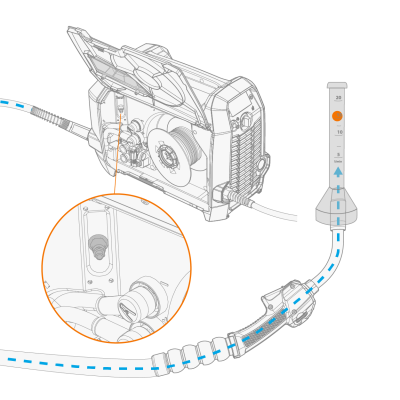

If the filler wire is installed, release the pressure arm of the wire feed mechanism to prevent wire feeding. |

|

7.

|

Start gas flow by using the gas test function in the system settings or by pressing the welding gun trigger. |

|

8.

|

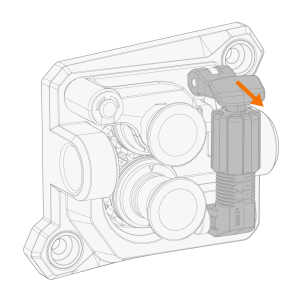

Check and adjust the gas flow. Use the built-in gas regulating valve (Master M 323 only), or an external flow meter and regulator for measuring and adjustment. |

Recommended gas flow rates (for general guidance only):

| Argon |

5...15 l/min |

10...25 l/min |

| Helium |

15...30 l/min |

- |

| Argon + 18-25% CO2 |

- |

10...25 l/min |

| CO2 |

- |

10...25 l/min |

* Depending on the gas nozzle size.

** Depending on the gas nozzle size and welding current.