Welding torch angle and position for six-axis cobot

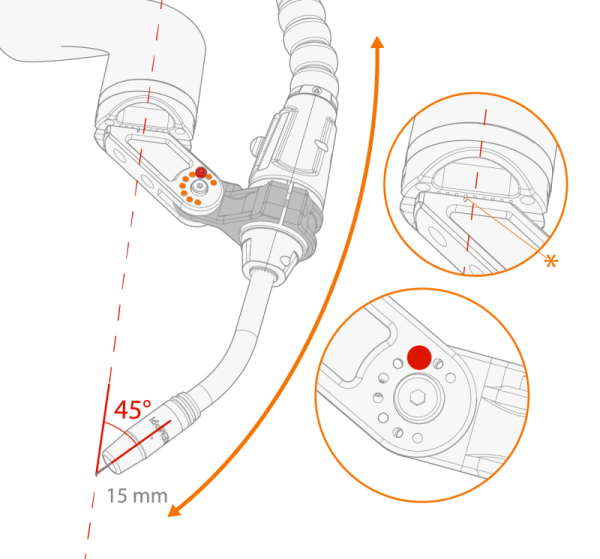

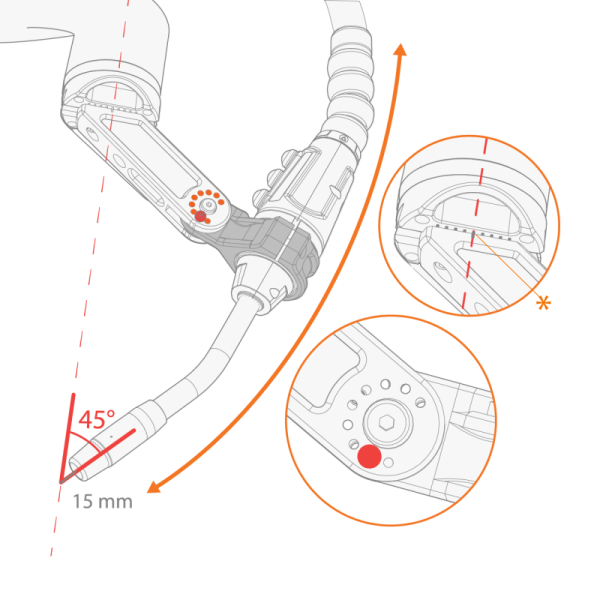

With a six-axis cobot, the optimal angle of the welding torch to the work piece is 45°. This section describes how to achieve the optimal welding torch angle and position with the Flexlite GXe-C welding torch neck angle and mounting bracket combinations. The filler wire stick-out length is 15 mm.

For more information, refer to Adjusting welding torch angle and Adjusting welding torch position.

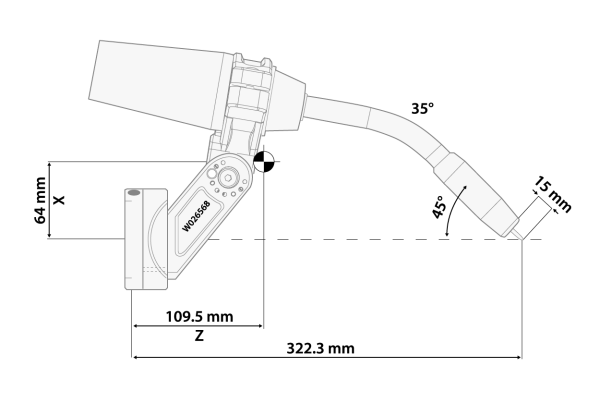

Flexlite GXe-C welding torch with a neck angle of 35°

Use the GXe-C Bracket Flex Mount S with the Flexlite GXe-C welding torch with a neck angle of 35° and adjust as follows (note the alignment mark *):

|

Dimensions and center of mass position in optimal setup:

Weight without cable pack: 1.5 kg |

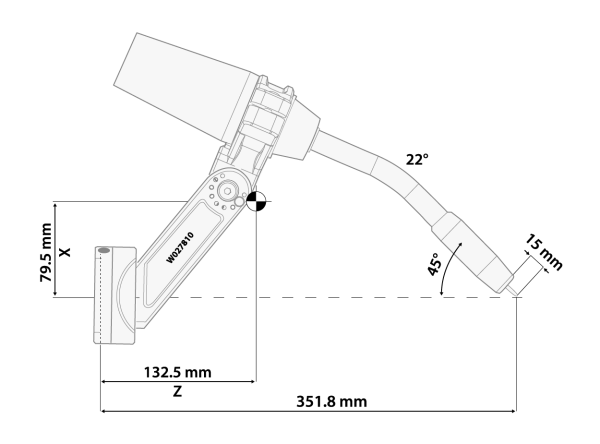

Flexlite GXe-C welding torch with a neck angle of 22°

Use the GXe-C Bracket Flex Mount M with the Flexlite GXe-C welding torch with a neck angle of 22° and adjust as follows (note the alignment mark *):

|

Dimensions and center of mass position in optimal setup:

Weight without cable pack: 1.6 kg |