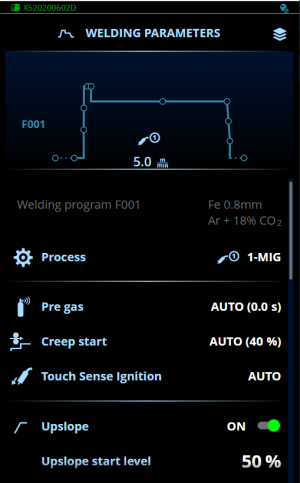

| Welding program |

|

Displays the welding program in use. You cannot change the welding program in this view. For changing a welding program, refer to Applying welding programs. |

Process

|

MIG, 1-MIG, Pulse, DPulse, WiseRoot+, WiseThin+, MAX Cool, MAX Speed, MAX Position |

This MIG welding process selection depends on the active welding program.

For more information on the additional processes, refer to Additional guidance to functions and features.

|

| Pre gas |

0.0 ... 9.9 s, Auto, step 0.1

0.0 = OFF

Default = Auto |

Welding function that starts the shielding gas flow before the arc ignites. This ensures that the metal does not

come into contact with air at the start of the weld. Time value is preset by the user. Used for all metals, but especially for stainless steel, aluminum and titanium. |

| Creep start |

10 ... 100 %, Auto, step 1

Default = Auto |

The Creep start function defines the wire feed speed before the welding arc ignites, that is, before the filler wire

comes in contact with the workpiece. When the arc ignites, the wire feed speed is automatically switched to the normal user-set speed. The Creep start function is always on. |

| Touch Sense Ignition |

AUTO/OFF/ON

Default = Auto |

Touch Sense Ignition delivers minimum spatter and stabilizes the arc immediately after ignition. |

| Upslope |

ON/OFF

Default = OFF |

Upslope is a welding function that determines the time, during which the welding current gradually increases to the desired

welding current level at the start of the weld. The upslope start level and time are preset by the user. |

| - Upslope start level |

10 ... 100 %, Auto, step 1

Default = 50 |

| - Upslope time |

0.1 ... 5 s, Auto, step 0.1

Default = 0.1 |

| Hot start |

ON/OFF

Default = OFF |

Welding function that uses higher or lower wire feed speed and welding current at the start of the weld. After the

Hot start period the current changes to normal welding current level. This facilitates the start of the weld especially

with aluminum materials. The Hot start level and time are adjustable by the user. The Hot start slope time adjustment sets the transition time from the Hot start phase to the normal welding current level. The Hot start fine tuning (voltage) is adjustable with 1-MIG, Pulse, DPulse, WiseThin+ and MAX Speed processes. |

| - Hot start level |

-50 ... +200 %, Auto, step 1

Default = 140 |

| - Hot start fine tuning |

-10.0 ... +10.0, step 0.1

Default = 0 |

| - Hot start time |

0.1 ... 9.9 s, Auto, step 0.1

Default = 1.2 s |

| - Hot start slope time |

0.0 ... 10.0 s, step 0.1 s

Default = 0 |

| Wise feature |

None, WiseFusion, WisePenetration, WiseSteel |

When selected, a list of available Wise features is opened for selection. For more information, refer to Additional guidance to functions and features.

(Not available with WiseRoot+, WiseThin+, MAX Cool, MAX Speed and MAX Position.) |

| Wire feed speed |

0.5 ... 25 m/min, step 0.05 or 0.1

Default = 5.00 m/min

|

Wire feed speed adjustment. When the wire feed speed is less than 5 m/min, the adjustment step is 0.05 and when the wire feed speed is 5 m/min or more, the adjustment step is 0.1.

|

| Wire feed speed limit min |

Min/Max = 0.5 ... 25 m/min, step 0.1

Default = 0.5 m/min |

Minimum and maximum limits for the wire feed speed adjustment. |

| Wire feed speed limit max |

Min/Max = 0.5 ... 25 m/min, step 0.1

Default = 25 m/min |

Current

|

10 ... machine size A, step 1

Default = 50 A |

Welding current adjustment. With WisePenetration only. |

| Fine tuning |

Example: -10.0 ... +10.0 V *, step 0.1

|

Fine tuning of the welding voltage.

* The voltage range for fine tuning is defined by the active welding program. |

| Dynamics |

-10.0 ... +10.0, step 0.2

Default = 0 |

Controls the short circuit behavior of the arc. The lower the value the softer the arc, the higher the value the

rougher the arc. |

| Robot travel speed |

20...2000 mm/min, step 1 /

Controlled by robot

Default = Controlled by robot |

The user can set the travel speed in a memory channel to be transmitted to the robot. However, note that:

- The robot must have a function that enables the use of the value transmitted from the memory channel.

- The travel speed can still be set directly in the robot program, in which case the value of the robot program overrides the value transmitted from the memory channel. |

| Crater fill |

ON/OFF |

When welding with high power, a crater is usually formed at the end of the weld. The Crater fill function

decreases the welding power / wire feed speed at the end of the welding job so that the crater can be filled using a

lower power level.

The Crater fill fine tuning (voltage) is adjustable with 1-MIG, Pulse, DPulse, WiseThin+ and MAX Speed processes. |

| - Crater fill start level |

10 ... 150 %, Auto, step 1

Default = 100 |

| - Crater fill fine tuning |

-10.0 ... +10.0, step 0.1

Default = 0 |

| - Crater fill time |

0.1 ... 10.0 s, Auto, step 0.1

Default = 1.0 s |

| - Crater fill end level |

10 ... 150 %, Auto, step 1

Default = 30 |

| - Crater fill end level time |

0.1 ... 10.0 s, step 0.1

Default = 0.0 s |

| Post current |

-30 ... +30 |

Post current setting affects the wire length at the weld end, for example to prevent the wire from stopping too close to the weld pool. This also enables the optimum wire length for the start of the next weld. |

| Wire feed end step (WF end step) |

OFF/ON

Default = OFF |

Wire feed end step feature prevents the filler wire from sticking to the contact tip when the welding ends. |

| Post gas |

0.0 ... 9.9 s, Auto, step 0.1

0.0 = OFF

Default = Auto |

Welding function that continues the shielding gas flow after the arc has extinguished. This ensures that the hot

weld does not come into contact with air after the arc is extinguished, protecting the weld and also the electrode. Used for all metals. Especially stainless steel and titanium require longer post gas times. |

![]() Pulse/DPulse welding parameters

Pulse/DPulse welding parameters