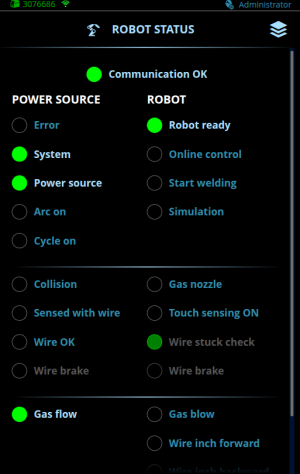

Robot status

The robot status view displays the communication between the power source and the robot. For more information on status and control parameters, refer to Status information and Control information.

| Parameter | Description |

|---|---|

| General | |

| Communication OK | Green light: The communication between the welding system and the robot works. No light: The communication between the welding system and the robot does not work. |

| Power source | |

| Error | No light: No errors are active. Red light: There is an error in the welding system that prevents welding. Select the error symbol for more information. |

| System | Green light: The welding system is ready for welding. All system devices are correct and working. No light: The welding system is not ready for welding. |

| Power source | Green light: The power source is ready to start a new weld. No light: The power source is not ready to start a new weld. |

| Arc on | Green light: The welding arc is established. No light: The welding arc is not established. |

| Cycle on | Green light: The welding cycle is in progress (the pre gas and post gas phases are included in the welding cycle). No light: The welding cycle is complete. |

| Collision | Red light: A collision is detected. No light: No collision is detected. |

| Sensed with wire / gas nozzle | Green light: A contact between the touch sensor (gas nozzle or wire) and the work piece has been detected. No light: No touch is sensed. |

| Wire OK | Green light: The filler wire is not stuck to the weld. No light: The filler wire is stuck to the weld. (An error message is displayed.) For more information, refer to Robot settings. |

| Water flow | Green light: Coolant is circulating. No light: Coolant is not circulating. |

| Gas flow | Green light: OK. The gas flow rate is above the minimum gas flow rate set in AX Manager. Note that if the gas flow sensor (available in R500 Wire Feeder EUR+ only) is set to OFF, this status is OK even if the gas flow rate is below the gas flow rate set in AX Manager (for more information, refer to Robot settings).

Yellow light: The gas flow rate is below the minimum gas flow rate set in AX Manager. No light: There is no gas flow. |

| Wire brake | R500 Wire Feeder HD EUR+ only. Indicates if the wire brake is active (the wire is currently being held in place). Green light: Wire brake is active. No light: Wire brake is not active. |

| Robot | |

| Robot ready | Green light: The robot is ready to start a new weld. Note that in those fieldbus control tables that do not support this field, the status is always 'Robot ready'. No light: The robot is not ready to start a new weld. |

| Online control | Green light: Online control mode is enabled. In online control mode, the robot controls the values of certain parameters directly. No light: Online control mode is not enabled. The values of the parameters come from the active memory channel. For more information, refer to Online control. |

| Start welding | Green light: The robot has requested welding or simulation if the simulation mode is on. No light: The robot has not requested welding or simulation. |

| Simulation | Green light: The simulation mode is on. The StartWelding control bit

controls the simulation cycle. In simulation mode the arc is not lit and wire is not fed. No light: The simulation mode is off. The StartWelding control bit controls the welding cycle. |

| Touch sensing ON | Green light: Touch sensing is used. No light: Touch sensing is not used. |

| Wire stuck check | Dark green light: Wire stuck detection is ON. A wire stuck check is performed automatically at the end of each weld to detect if the filler wire is stuck to the weld. Green light: Wire stuck check is ongoing. No light: Wire stuck detection is set to OFF or 'Select at robot' and the robot has not requested a wire stuck check. For more information, refer to Robot settings. |

| Gas blow | Green light: The shielding gas valve is open for gas blow. No light: The shielding gas valve is closed. |

| Wire inch forward | Green light: The wire inch forward function is ON. No light: The wire inch forward function is OFF. |

| Wire inch backward | Green light: The wire inch backward function is ON. No light: The wire inch backward function is OFF. |

| Gas nozzle | Green light: Gas nozzle is used for touch sensing. No light: Filler wire is used for touch sensing. |

| Air blow | R500 Wire Feeder EUR+ models only. Green light: The compressed air valve is open. The compressed air valve cannot be opened during welding or simulation. No light: The compressed air valve is closed. |

| Wire brake | R500 Wire Feeder HD EUR+ only. Dark green light: The wire brake is set to Auto and the wire is currently being held in place. Dark green color, no light: The wire brake is set to Auto but the wire brake is not active (the wire is not being held in place at the moment). Grayed: The wire brake is set to OFF. No light: The wire brake is set to OFF or 'Select at robot' and the robot has not requested the wire brake to be active. |