X8 SuperSnake GT02XW Manual 1920890, rev. 1944

送丝轮压力调整

在调整辊安装在压柄上时调整送丝轮压力。在焊丝脱离焊枪导电嘴末端时,施加的负载应足以克服手对焊丝形成的轻微制动力。

|

对于直径较小和柔软的焊丝,需要的送丝压力也更小。参阅本章末尾的表格,获取更多指导。 |

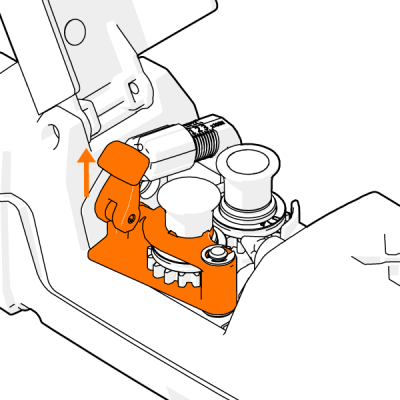

| 1. | 抬起压柄,从而将其松开。 |

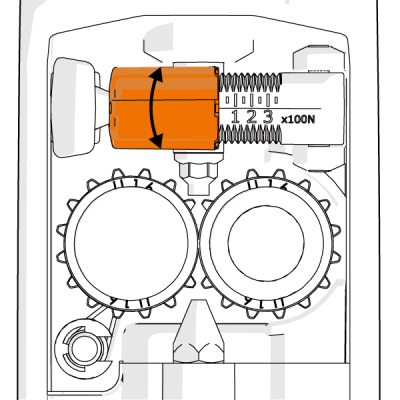

| 2. | 转动压柄上的辊筒调节器,调节送丝轮压力。调节辊旁边的刻度尺表示以牛顿 (N) 为单位的压力负荷。欲了解正确的压力值,请参阅本节末尾的表格。 |

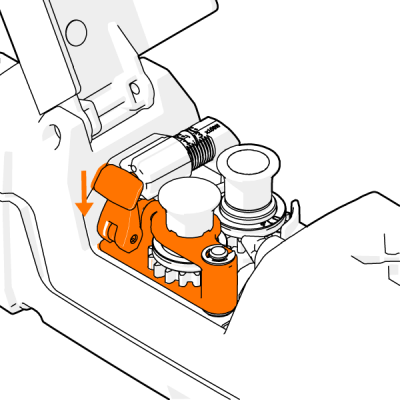

| 3. | 压下压柄,锁定调整。 |

|

压力过大会压平焊丝,并损坏焊丝镀层或药芯。压力过大还会导致不必要的送丝轮磨损和增加变速箱负荷。 |

|

不建议在使用 X8 SuperSnake GT02XW 中继送丝机的 X8 MIG Welder 送丝机装置中使用滚花送丝轮。 |

|

在 X8 送丝机设置中选择 X8 SuperSnake GT02XW 中继送丝机后,当按下送丝器面板上的冷送丝按钮时,冷送丝功能会自动将焊丝送入系统。 |

| 填充焊丝类型 | 送丝轮轮廓 | 填充焊丝直径,ø mm | 调节 (x100N) | |

|---|---|---|---|---|

| Fe, Ss | V 形槽 |

|

1.0 | 1.5−2.0 |

| ≥ 1.2 | 2.0−3.0 | |||

| Fc, Mc | V 形槽,带滚花 |

|

≥ 1.2 | 1.0−2.0 |

| 1.6 | 2.0−3.0 | |||

| 铝 | U 形槽 |

|

1.2 | 1.0−1.5 |

| 1.6 | 2.0−2.5 | |||