X8 SuperSnake GT02XW Manual 1920890, rev. 1944

Wire liner replacement

The wire liner is a consumable part, which needs to be changed if worn and when the filler wire material changes.

|

If you change the filler wire to a different diameter or material, change also the feed rolls accordingly. |

|

The filler wire must be removed from the subfeeder system before the wire liner replacement. |

Tools needed:

| • | 10 mm socket, long |

| • | Socket wrench |

| • | 10 mm spanner |

| • | 8 mm spanner |

| • | Side cutting pliers |

| • | Carpet knife. |

Remove old liner:

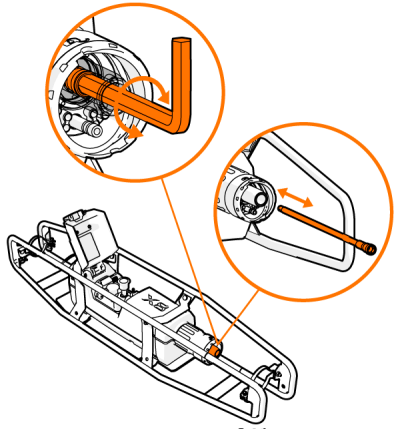

| 1. | Disconnect the cables from the subfeeder and from the wire feeder. |

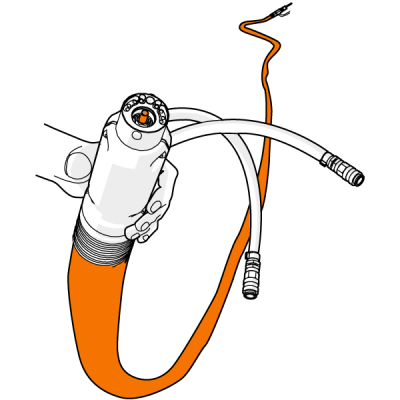

| 2. | Fully straighten the cable pack and ensure that the cable is not twisted. |

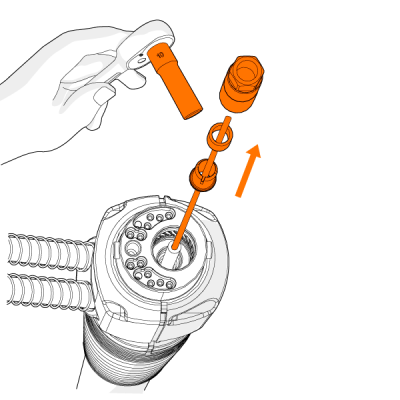

| 3. | Release and remove the liner sleeve along with the cone and seal at the subfeeder end of the cable. |

|

Ensure that you don't damage the springs inside.

|

| 4. | Release and remove the long liner sleeve along with the cone and seal at the wire feeder end of the cable. |

| 5. | Take the old liner out from the hose, pulling from the subfeeder end. |

Install new liner:

| 1. | Replace the short wire guide in the end of the liner's long sleeve. |

| 2. | Start feeding the new liner into the hose from the wire feeder end. Stop when there is approximately 100…200 mm of liner left outside the cable connector end. |

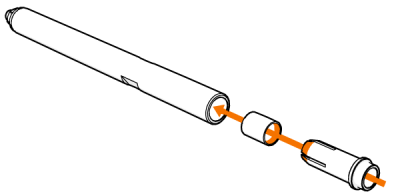

| 3. | Insert the long liner sleeve along with the cone and the seal on the liner end. |

|

Use the correct sleeve with your wire liner. The sleeve for the orange liner (DL Chili) is different from the one for the green liner (Fe liner, steel spiral). |

| 4. | Push the rest of the liner into the cable with the long sleeve. |

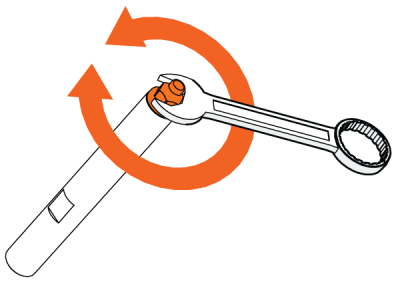

| 5. | Secure the long sleeve at the wire feeder end of the cable hose. |

| 6. | Insert the liner sleeve along with the cone and seal on the liner at the subfeeder end of the cable hose. |

| 7. | Secure the sleeve at the subfeeder end of the cable hose. |

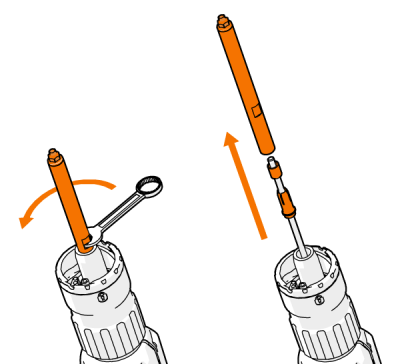

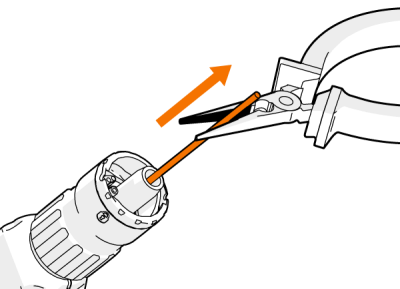

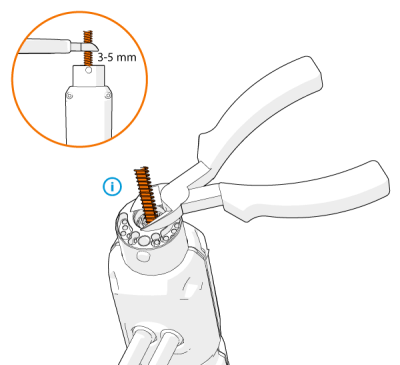

| 8. | At the subfeeder end of the cable hose, cut the excess wire liner leaving approximately 3…5 mm extruding from the cable connector end level. |

|

Cut the excess of the steel liner with side cutting pliers and the excess of the Chili liner with a carpet knife. |

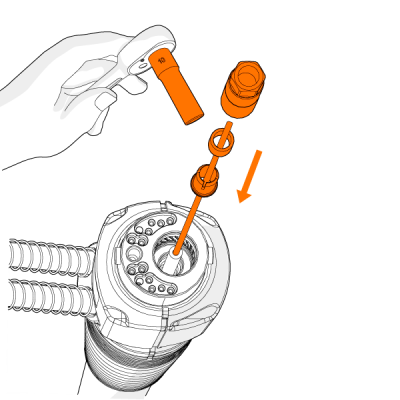

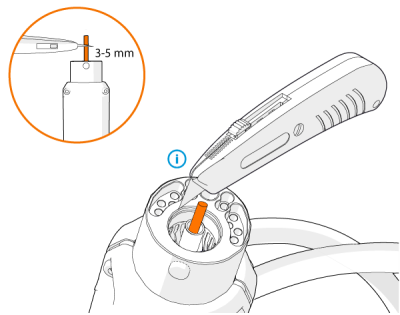

Replace filler wire inlet guide liner:

| 1. | Install the new filler wire inlet guide liner. Tighten the component in place with an Allen key. |