Welding data collection: alarms in WeldEye services

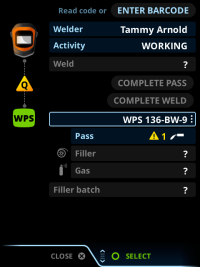

Before welding, Control Pad shows alarms for insufficient welder qualifications, wrong filler material, and wrong shielding gas. After welding, it shows an alarm if there are nonconforming welding parameters or heat input values.

Each welder's qualifications are stored in their personal qualification certificates in WeldEye. If a welder's certificate lacks the necessary qualifications required by the WPS, the system raises an alert. If the welder restrains from welding, the system drops the alert. However, if the welder starts to weld despite the alert, the system records the alert in the WeldEye cloud service.

WeldEye also compares the filler material information and shielding gas information that the welder enters with Control Pad to the filler and shielding gas defined in the WPS. If these do not match, the system raises an alert.

Figure: The welder is not qualified for welding with the selected WPS

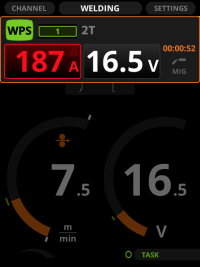

Control Pad shows the welding current and voltage during welding and indicates whether the values are within the limits of the WPS. This information may be useful for the bystanders observing the welding. The values are shown in white, yellow or red.

White: The measured value is within the WPS limits or the WPS is not identified.

Yellow: The measured value is near the WPS limits. (Warning)

Red: The measured value is outside the WPS limits. (Alert)

There is a short reaction time, usually a few seconds, before the color changes. This makes the display easier to read and enables monitoring of the overall welding quality.

For more information, see WeldEye help on Real-time WPS monitoring.