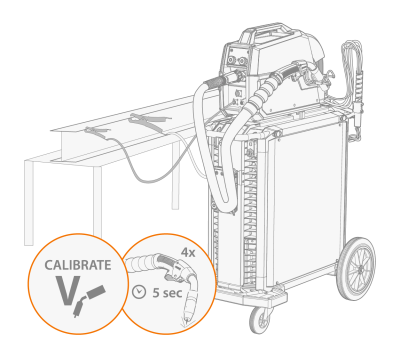

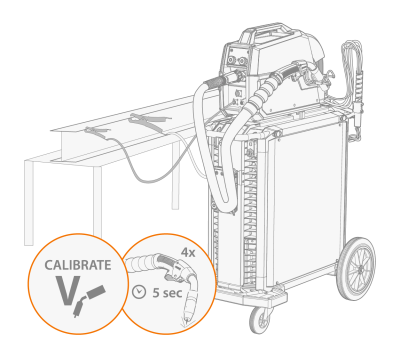

Calibrating arc voltage

X8 MIG Welder measures the voltage of the welding arc and the voltage loss in the interconnection cable and welding gun. After calibration, the power source calculates the arc voltage, if the voltage sensing cable is not connected.

Figure: Calibration of the welding cables:

Proceed as follows:

|

1.

|

Ensure that the measurement cable connects the wire feeder and the power source. |

|

2.

|

Connect the voltage sensing cable from the wire feeder to the welding piece. |

|

3.

|

Adjust the welding parameters. |

|

4.

|

Weld for at least 4 welds of 5 seconds. |

>> With several welds, the measurement result is more accurate.

>> The welder calibrates to the length of the interconnection cable. The values are saved, so you only need to calibrate once after installing the welder package.

|

5.

|

After the calibration, you can view arc voltage on Control Pad and the wire feeder control panel during and after welding. To view the arc voltage on Control Pad display, select Voltage display mode. Arc voltage is the default setting. |

|

It is recommendable to keep the voltage sensing cable connected at all times. However, if the cable is not connected, the power source calculates the arc voltage according to the calibrating values. |

|

Repeat steps 1-4 every time you change the length of the interconnection or earth return cable. |