X5 FastMig Manual 1920960, rev. 2551

Installation

|

Do not connect the equipment to the mains before the installation is complete. |

|

Do not modify the welding equipment in any way, except for the changes and adjustments covered in the manufacturer’s instructions. |

|

Do not attempt to move or hang the equipment mechanically (e.g. with a hoist) from the handle on the power source unit or on the wire feeder unit. The handles are for manual moving only. |

|

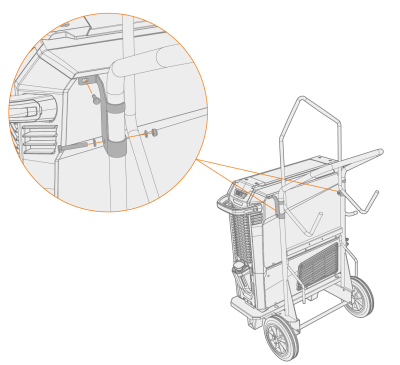

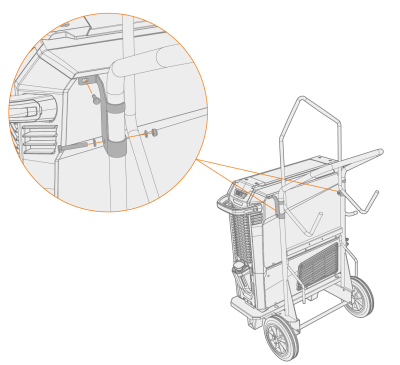

When installing the full set of equipment stacked as a tower – water cooler at the bottom, power source in the middle and wire feeder at the top – always install and secure the equipment onto a Kemppi cart compatible with X5 FastMig or secure the equipment to other adequate support on site.

|

|

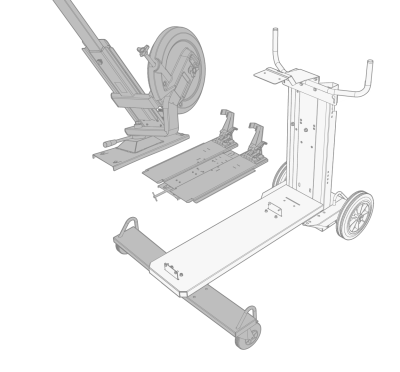

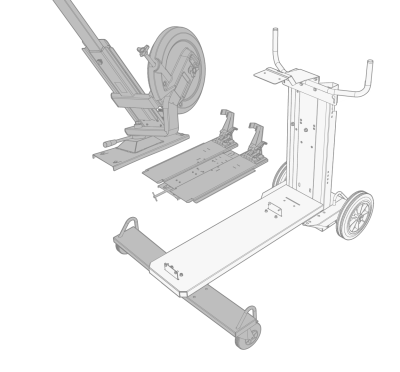

When installing the full set of equipment stacked as a tower and using the double wire feeder rotating plate or counterbalance arm, always use the broader front roller support plate delivered with the equipment. This applies to the 4 wheel cart.

|

|

Place the machine on a horizontal, stable and clean ground. Protect the machine from rain and direct sunshine. Check that there is enough space for cooling air circulation in the machine vicinity. |

Before installation

|

•

|

Make sure to acknowledge and follow the local and national requirements regarding installation and use of high voltage units. |

|

•

|

Check the contents of the packages and make sure the parts are not damaged. |

|

•

|

Before you install the power source on site, see the requirements for the mains cable type and fuse rating. |

Distribution network

|

This Class A equipment is not intended for use in residential locations where the electrical power is provided by the public low-voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations, due to conducted as well as radiated radio-frequency disturbances. |

|

Provided that the short circuit power of public low voltage system at the point of common coupling is higher than mentioned in the table below (*), the equipment is compliant with IEC 61000-3-11:2017 and IEC 61000-3-12:2011 and can be connected to public low voltage systems. It is the responsibility of the installer or user of the equipment to ensure, by consultation with the distribution network operator if necessary, that the system impedance complies with the impedance restrictions.

|

| X5 power source 400A: |

5.8 MVA |

| X5 power source 500A: |

6.4 MVA |

| X5 pulse power source 400A: |

6.3 MVA |

| X5 pulse power source 500A: |

6.7 MVA |