Installing gas bottle and testing gas flow

|

Handle gas bottles with care. There is a risk of injury if the gas bottle or the bottle valve is damaged! |

|

Always secure the gas bottle properly in an upright position to a special holder on the wall or on the welding equipment cart. Always keep the gas bottle valve closed when not welding. |

|

- If a transport unit with a gas bottle rack is used, install the gas bottle on the transport unit first, then make the connections. - Install the welding gun to the wire feeder before installing and testing the gas bottle. - Do not use the whole contents of the bottle. - Always use an approved and tested regulator and flow meter. |

Contact your local Kemppi dealer for choosing the gas and the equipment.

| 1. | Without gas bottle cart: Place the gas bottle in a suitable, secure location. |

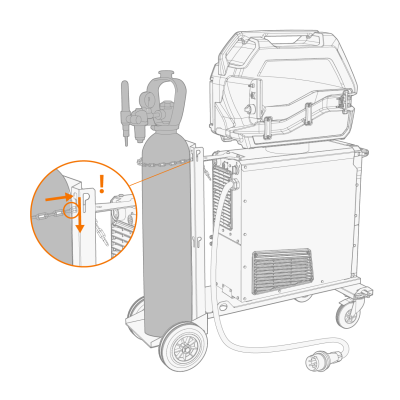

| 2. | With gas bottle cart: Move the gas bottle on the transport unit's gas bottle rack and secure it in place with the chain provided. |

>> Take the chain through the top part of the keyhole slot and drop it down into the keyhole slot's narrow section to lock the chain in place.

| 3. | If not already, connect the welding torch to the wire feeder. |

| 4. | Connect the gas hose to the wire feeder. |

| 5. | Open the gas bottle valve. |

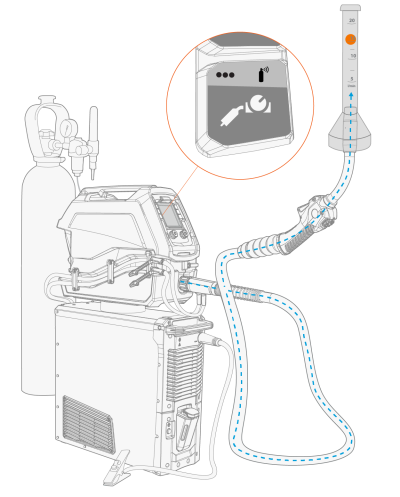

| 6. | Press the gas test button in the wire feeder control panel to flush the previous shielding gas and to run the new gas into the system. |

>> In X3 wire feeder the gas test function is activated by long-pressing the remote control selection button in the control panel.

|

Use the gas test function also to test that the shielding gas flows through the system properly. |

| 7. | Press the gas test button again to adjust the gas flow. Use an external flow meter and regulator for measuring and adjustment. |

>> In X3 wire feeder the gas test function is activated by long-pressing the remote selection button in the control panel.

Recommended gas flow rates (for general guidance only):

| MIG* | |

|---|---|

| Argon | 10...25 l/min |

| Helium | - |

| Argon + 18-25% CO2 | 10...25 l/min |

| CO2 | 10...25 l/min |

* Depending on the gas nozzle size and welding current.