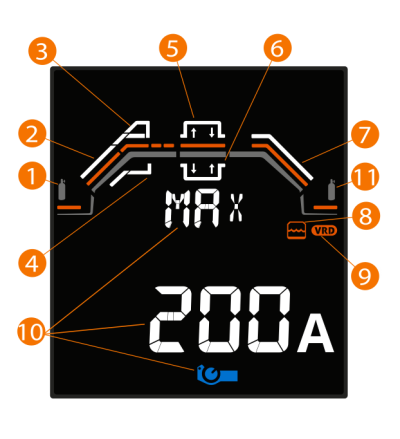

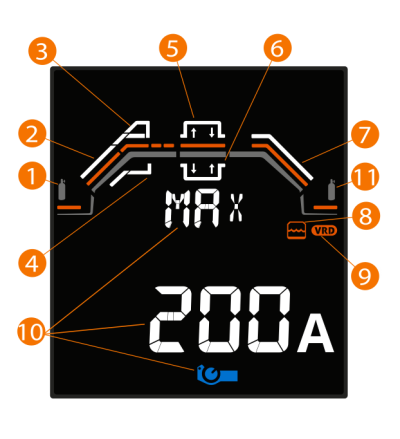

Welding parameters

The Welding parameters view includes a start and stop curve for visualizing and adjusting the parameters for a weld. You can access the welding parameters by pressing the control panel's Welding parameters and TIG HF ignition button (refer to Minarc T 223 ACDC control panel).

|

Many of the welding parameters are welding process specific and are visible and available for adjustment accordingly. |

|

3.

|

Hot start, positive values |

|

4.

|

Hot start, negative values |

|

5.

|

Minilog, positive values |

|

6.

|

Minilog, negative values |

|

10.

|

Min/Max current limit for remote control |

The white line indicates that the parameter is on. The orange line indicates that the parameter value is currently adjustable. If the Auto value of a parameter is used, its numerical value is displayed below the start and stop curve.

The parameters are explained in the 'Welding parameters' table below.

Adjusting welding parameters

|

1.

|

Turn the control knob so that the orange line appears at the desired welding parameter (here the Upslope parameter is used as an example). |

|

2.

|

Press the control knob button to select the welding parameter for adjustment. |

|

3.

|

Turn the control knob to adjust the welding parameter value. |

|

4.

|

Confirm the new value / selection by pressing the control knob button. |

| Tip: When a parameter value is adjustable, you can select the parameter's default value by long-pressing the control knob button. This works for all parameters except water cooling and VRD. |

Welding parameters

TIG welding parameters

TIG welding parameters

The parameters listed here are available for adjustment with the TIG welding process.

| Pre gas |

0.0 ... 10 s, Auto, step 0.1

Default = Auto

|

Pre gas is a welding function that starts the shielding gas flow before the arc ignites. This ensures that the metal does not

come into contact with air at the start of the weld. Used for all metals, but especially for stainless steel, aluminum and titanium.

When Auto is selected the pre gas is determined automatically according to the welding current. |

Upslope

|

0.0 ... 5 s, step 0.1

Default = 0 s |

Upslope is a welding function that determines the time, during which the welding current gradually increases to the desired welding current level at the start of the weld. |

| Hot start |

ON/OFF

Default = OFF |

Welding function that uses higher or lower welding current at the start of the weld. After the Hot start period the current changes to normal welding current level. This facilitates the start of the weld especially with aluminum materials. The Hot start time is used only in 2T trigger mode. |

| - Hot start level |

-80 ... +100 %, step 1

Default = +30 %

|

| - Hot start time |

0.1 ... 9.9 s, step 0.1

Default = 1.2 s |

| Minilog level |

-99 % ... 125 %, step 1

Default = -80 % |

Minilog is a TIG welding function, which allows using the torch switch to change between the welding current and Minilog current which can be lower or higher than the welding current. For more information, refer to Trigger logic functions.

For information on setting Minilog to ON, refer to Minarc T 223 ACDC control panel. |

| Downslope |

0.0 ... 1.5 s, step 0.1

Default = 0.1 s |

Downslope is a welding function that determines the time during which the welding current gradually decreases to the end current level. |

| Post gas |

0.0 ... 9.9 s, Auto, step 0.1

Default = Auto |

Post gas is a welding function that continues the shielding gas flow after the arc has extinguished. This ensures that the hot

weld does not come into contact with air after the arc is extinguished, protecting the weld and also the electrode. Used for all metals. Especially stainless steel and titanium require longer post gas times.

When Auto is selected the post gas is determined automatically according to the welding current. |

| Water cooling |

OFF/Auto/ON

Default = Auto |

When ON is selected, the coolant is circulated continuously, and when Auto is selected, the coolant is circulated only during welding.

This parameter applies to all memory channels. |

| Remote control min |

Min = Current limit minimum

Max = Current limit maximum

|

Minimum and maximum welding current limits for remote control.

These parameters are used to limit the current adjustment range for analog remote controls.

The current limits do not apply to the TXR20 rocker switch remote control. |

| Remote control max |

MMA welding parameters

MMA welding parameters

The parameters listed here are available for adjustment with the MMA welding process.

| Hot start level |

-10 ... +10, step 1

Default = 0

|

Welding function that uses higher or lower welding current at the start of the weld. After the Hot start period the current changes to normal welding current level. This facilitates the start of the weld especially with aluminum materials. |

| VRD |

ON/OFF

Default = OFF

(In AU power source models VRD is locked ON) |

Voltage reduction device (VRD) reduces the open-circuit voltage to maintain below a certain voltage value.

This parameter applies to all memory channels.

|

| Remote control min. |

Min = Current limit minimum

Max = Current limit maximum

|

These parameters are used to limit the current adjustment range for analog remote controls.

The current limits do not apply to the TXR20 rocker switch remote control. |

| Remote control max. |

Cleaning and polishing parameters

Cleaning and polishing parameters

The parameters listed here are available for adjustment with the cleaning and polishing processes.

| Water cooling |

OFF/Auto/ON

Default = Auto |

When ON is selected, the coolant is circulated continuously, and when Auto is selected, the coolant is circulated only during cleaning and polishing.

This parameter applies to all memory channels. |

| Remote control min. |

Min = Current limit minimum

Max = Current limit maximum

|

Minimum and maximum current limits for remote control.

These parameters are used to limit the current adjustment range for analog remote controls.

The current limits do not apply to the TXR20 rocker switch remote control. |

| Remote control max. |

![]() Cleaning and polishing parameters

Cleaning and polishing parameters