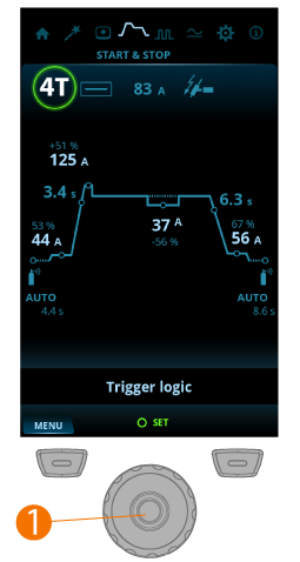

Start & stop sequence view

The parameters diagram view makes base parameter identification and setting easy. From pre-gas time to post-gas time and everything in between, you can quickly select and adjust the needed parameter value.

To adjust parameters:

| 1. | Go to the Start & stop sequence view. |

| 2. | Turn the control knob (1) to browse through the parameters. |

| 3. | Select a parameter for adjusting by pressing the control knob button (1). |

| 4. | Adjust the parameter by turning the control knob (1). |

| 5. | Close the parameter setting by pressing the control knob (1). |

Adjustable parameters in all welding modes:

| Parameter | Value | Description |

|---|---|---|

| Trigger logic | 2T / 4T / 4T LOG / 4T LOG + Minilog (Default = 2T) | Welding torches have two alternative operation modes: 2T and 4T. They differ in the way how the trigger operates. In 2T mode you hold the trigger down while welding, whereas in 4T mode you press and release the trigger to start or to stop welding and to use special trigger functions, such as Minilog. |

| Welding mode | Continuous / Spot / MicroTack | Continuous welding: Normal TIG welding which doesn’t have any pause times. Spot welding: TIG welding function, which automatically produces a weld of predefined duration. Parameters are preset by the user. This function is used for attaching two pieces of materials with tack welds, for example joining thin sheets with low heat input. MicroTack: TIG welding function, which optimizes the spot welding characteristics. Used for tack welding of thin sheets or materials of different thicknesses. Allows fast and easy creation of clean tack welds with minimum heat input. |

| Welding current | Default = 50 A | |

| Ignition mode | Lift TIG / High frequency (HF) ignition | The way in which the welding arc is ignited. In TIG welding, two ignition modes are available: High Frequency (HF) ignition and Lift TIG ignition. The HF ignition uses a voltage pulse to initiate the arc, and the Lift TIG ignition needs a physical contact between the electrode and the work piece. |

Adjustable parameters in continuous welding:

| Parameter | Value | Description |

|---|---|---|

| Pre gas | 0.0 s ... 10.0 s, Auto, 0.1 s step (Default = Auto) | Welding function that starts the shielding gas flow before the arc ignites. This ensures that the metal does not come into contact with air at the start of the weld. Time value is preset by the user. Used for all metals, but especially for stainless steel, aluminum and titanium. |

| Search arc | OFF / 5 % ... 90 %, step 1 % (Default = OFF) | Welding function that allows using a brief low current period at the start of the weld. This enables precise start of welding. The parameters are preset by the user. |

| Upslope | OFF / 0.1 s ... 5.0 s, 0.1 s step (Default = 0.0 s) | Welding function that determines the time, during which the welding current gradually increases to desired welding current level at the start of the weld. The value for the upslope time is preset by the user. The value zero means the function is off. |

| Hot start level | -80 % ... 100 %, 1 % step (Default = OFF, 0 %) | Hot start: Welding function that uses higher welding current at the start of the weld. After the Hot start period the current drops to normal welding current level. The values for Hot start current level and its duration are preset manually. This facilitates the start of the weld especially with aluminum materials. |

| Hot start time | 0.1 s ... 5.0 s, 0.1 s step (Default = 1.2 s) | This is not available with 4T trigger logic. |

| Minilog level | -99 % ... 125 %, 1 % step (Default = OFF, 0 %) | Minilog: TIG welding function, which allows using the torch switch to change between the welding current and Minilog current. Parameters are preset by the user. Welding over tack welds is one application, and it also functions as a "pause current" when the welding position changes for example. |

| Downslope | OFF / 0.1 s ... 15.0 s (Default = 0.1 s) | Welding function that determines the time, during which the welding current gradually decreases to the end current level. The value for the downslope time is preset by the user. The value zero means the function is off. |

| Tail arc | OFF / 5 % ... 90 % (Default = OFF) | Welding function that allows using a brief low current period at the end of the weld. This reduces welding defects caused by end cratering. The parameters are preset by the user. The value zero means the function is off. |

| Post gas | 0.1 s ... 30.0 s / AUTO, 0.1 s step | Welding function that continues the shielding gas flow after the arc has extinguished. This ensures that the hot weld does not come into contact with air after the arc is extinguished, protecting the weld and also the electrode. Used for all metals. Especially stainless steel and titanium require longer post gas times. |

Adjustable parameters in spot welding:

| Parameter | Value | Description |

|---|---|---|

| Pre gas | 0.0 s ... 10.0 s, Auto, 0.1 s step (Default = Auto) | Welding function that starts the shielding gas flow before the arc ignites. This ensures that the metal does not come into contact with air at the start of the weld. Time value is preset by the user. Used for all metals, but especially for stainless steel, aluminum and titanium. |

| Upslope | OFF / 0.1 s ... 5.0 s, 0.1 s step (Default = 0.0 s) | Welding function that determines the time, during which the welding current gradually increases to desired welding current level at the start of the weld. The value for the upslope time is preset by the user. The value zero means the function is off. |

| Spot time | 0.0 s … 10.0 s, step 0.1 s (Default = 2.0 s) | Spot welding: TIG welding function, which automatically produces a weld of predefined duration. Parameters are preset by the user. This function is used for attaching two pieces of materials with tack welds, for example joining thin sheets with low heat input. |

| Downslope | OFF / 0.1 s ... 15.0 s (Default = 0.1 s) | Welding function that determines the time, during which the welding current gradually decreases to the end current level. The value for the downslope time is preset by the user. The value zero means the function is off. |

| Post gas | 0.1 s ... 30.0 s / AUTO, 0.1 s step (Default = Auto) | Welding function that continues the shielding gas flow after the arc has extinguished. This ensures that the hot weld does not come into contact with air after the arc is extinguished, protecting the weld and also the electrode. Used for all metals. Especially stainless steel and titanium require longer post gas times. |

Adjustable parameters in MicroTack welding:

| Parameter | Value | Description |

|---|---|---|

| Pre gas | 0.0 s ... 10.0 s, Auto, 0.1 s step (Default = Auto) | Welding function that starts the shielding gas flow before the arc ignites. This ensures that the metal does not come into contact with air at the start of the weld. Time value is preset by the user. Used for all metals, but especially for stainless steel, aluminum and titanium. |

| MicroTack spot time | 1 ms ... 200 ms, step 1 ms (Default = 10 ms) | MicroTack welding: TIG welding function, which optimizes the spot welding characteristics. Used for tack welding of thin sheets or materials of different thicknesses. Allows fast and easy creation of clean tack welds with minimum heat input. |

| MicroTack pause time | 50 ms ... 500 ms, step 1 ms (Default = 50 ms) | This is not visible in the settings if the MicroTack pulse count is only 1. |

| MicroTack spot count | 1 ... 5 / endless, step 1 (Default = 1) | If Lift TIG is used, MicroTack graph shows only 1 spot and the spot count parameter is not visible. |

| Post gas | 0.1 s ... 30.0 s / AUTO, 0.1 s step (Default = Auto) | Welding function that continues the shielding gas flow after the arc has extinguished. This ensures that the hot weld does not come into contact with air after the arc is extinguished, protecting the weld and also the electrode. Used for all metals. Especially stainless steel and titanium require longer post gas times. |