Weld Assist

Weld Assist is available for 1-MIG and pulse welding processes.

Weld Assist is a wizard-like utility for easy selection of welding parameters. The utility walks the user step-by-step through the selection of required parameters.

|

The currently selected welding program, including filler wire and shielding gas information, is shown and used as a basis in Weld Assist. If necessary, the welding program can be changed before continuing by selecting the default welding program and selecting a new one from the list. |

| 1. | Go to the Weld Assist view and select 'Next'. |

| 2. | Select: |

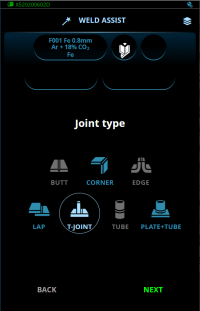

>> The welding joint type: T-joint / lap joint / corner joint / plate+tube joint

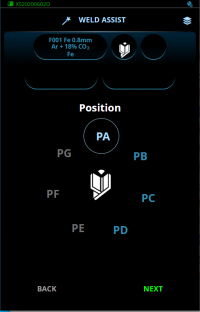

>> The welding position: PA / PB / PC / PD

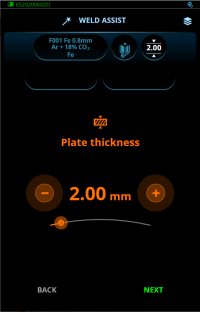

>> The plate thickness (1...12 mm)

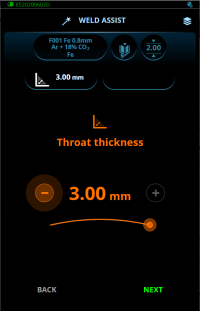

>> The throat thickness (1...6 mm). Note: Throat thickness cannot be selected with corner joint. With lap joint, the throat thickness cannot be selected when the plate thickness is 1...3 mm.

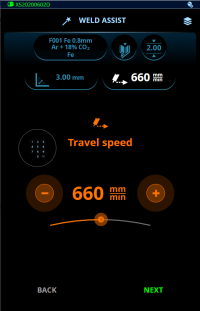

>> The travel speed (300...1500 mm/min)

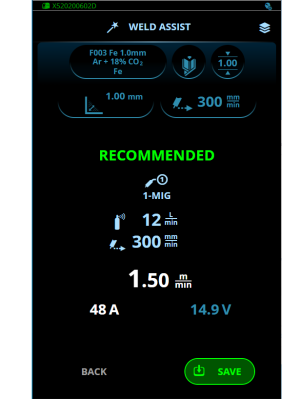

| 3. | Weld Assist gives you a recommendation for these welding parameters: |

>> Welding process

>> Gas flow rate (measured at the gun end)

>> Wire feed speed

>> Indicative values for welding current and voltage.

| 4. | Save the Weld Assist’s recommendation for welding settings by selecting 'Save'. |

| 5. | Select the memory channel slot for saving. |

| 6. | To use the memory channel, select 'Use' in Weld Assist, or later in the Memory channels view. |

The welding parameters created with Weld Assist are still adjustable as per normal.