Filling cooler and circulating coolant

Fill the cooler with pre-mixed coolant solution. The mixing ratio should be 20...50% as standard. Use only ethylene or propylene glycol mixture intended for welding cooling systems, for example Kemppi cooling liquid.

|

Do not add water to the pre-mixed coolant solution. Do not use automotive cooling solutions or ethanol-based mixtures. |

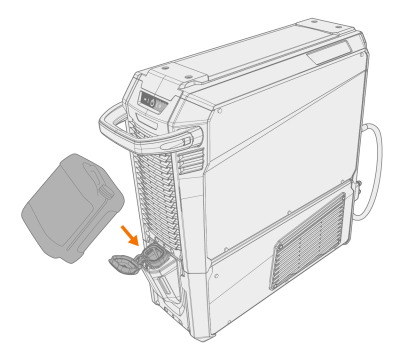

| 1. | Open the cooler cap. |

| 2. | Fill the cooler with coolant. Do not fill over the max. marking. |

| 3. | Close the cooler cap. |

To circulate coolant:

Press the coolant circulation button in the cooler front panel. It activates the motor, which pumps the coolant to the hoses and to the welding gun.

Complete the coolant circulation operation after each time you change the welding gun.

To test coolant flow sensor:

Obstruct the coolant flow by squeezing the coolant inlet hose until error code 26 (Cooling liquid not circulating) is displayed in AX Manager.

To adjust coolant flow sensor:

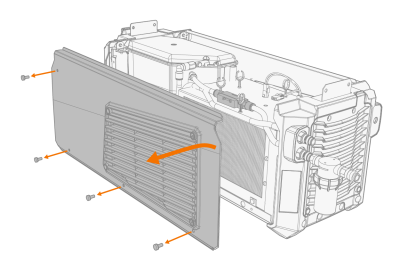

| 1. | Unscrew the mounting screws on the side of the cooling unit and remove the side plate. |

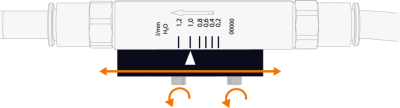

| 2. | Adjust the coolant flow sensor by loosening the locking screws on the slider and moving the slider to the desired flow rate. |

| 3. | Tighten the slider locking screws. |

| 4. | Replace the cooler side plate and tighten the mounting screws. |