Calibrating welding cable

Welding cable resistance can be measured using the built-in cable calibration function without an additional measurement cable.

|

For a successful calibration, use a clean/new contact tip and ensure that the work piece surface is clean. |

|

1.

|

Remove the welding torch gas nozzle. |

|

2.

|

Pull back the remaining filler wire from the welding torch by pressing the wire inch backward button (if necessary, cut the wire first). |

|

3.

|

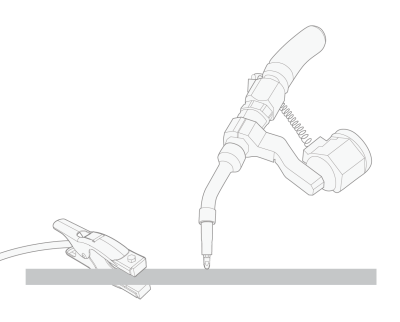

Place the welding torch at a right angle (90°) to approximately 1 mm from the work piece. |

|

4.

|

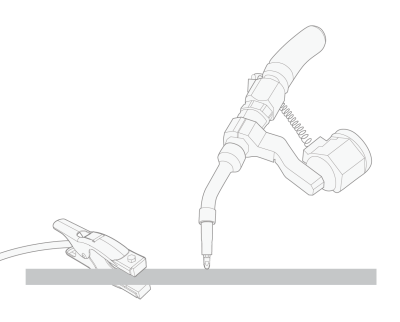

Move the welding torch so that the contact tip touches the work piece. |

|

The contact between the contact tip and the workpiece must be sufficient. However, the contact tip must not be pressed too hard against the work piece. |

|

5.

|

In AX Manager, go to Settings - Device settings and select Cable calibration and follow the on-screen instructions. |

|

6.

|

Check the measured values in AX Manager and repeat calibration if necessary (if, for example, the calibration failed due to poor contact between the contact tip and the work piece). |

|

7.

|

After calibration, lift the welding torch from the work piece, run the wire out of the contact tip and reattach the gas nozzle. |